I am modeling an auto plant and I would like to know what raw material loads I would need. (Steel, Iron Coal, etc, etc).

That will depend somewhat on the era you’re modelling and possibly even on the particular auto manufacturer. How about a little more info, please?

Wayne

Are you making an assembly plant? … If so, inbound auto parts are needed.

Are you building an auto parts plant? … Depends on the part. Body parts plant for example needs inbound sheet metal.

Assembly plants received engines, stampings, brakes, axels, glass, etc. raw materials would be delivered to a parts plant–steel for forging/casting engines, axels, etc. the parts plant would ship to the assembly plant.

the era in early 1950s

its a ford motor co. plant; its kinda a mix of everything, i know its not protypical but its my railroad my rules

It is prototypical for the Ford Rouge plant in Dearborn Michigan. It had an integrated steel mill and several assembly lines. There should be much about it on the internet.

Alex,

A starter. They probably made them there too!:

http://en.wikipedia.org/wiki/Ford_River_Rouge_Complex

General Motors, Images:

Frank

I’m not modelling the auto industry itself (takes up too much room), but I do model the traffic to and from it as interchange cars. That means lots of boxcars and automobile cars moving between interchange points:

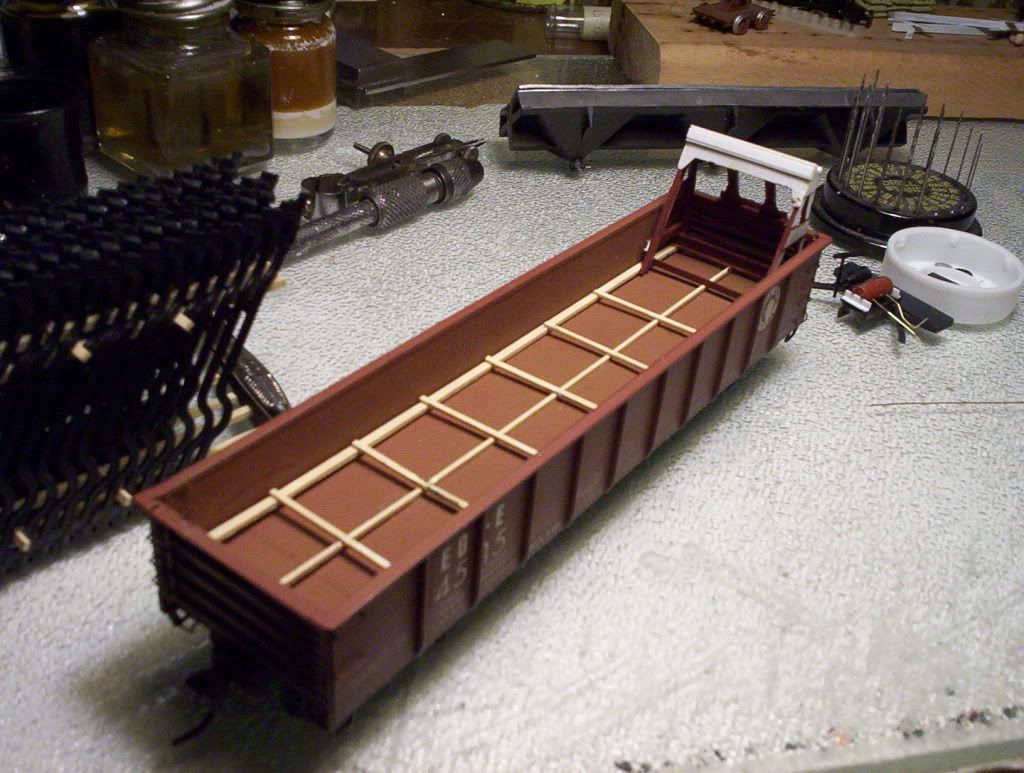

I also run gondolas loaded with frames from one staging yard to another (and back empty, too, of course):

The cars are in assigned service and equipped with semi-permanent racks. They’re also restricted from movement over certain home-road lines due to overhead clearance issues:

Wayne

For inbound loads I’m going to model: “-” means by way of

coal-hopper

coke-hopper

iron-gondola

steel-gondola

but what would rubber and glass come in

Here are my auto plants. The one on the left is the factory and the one on the right is the warehouse. now back to the question. What would sheets of glass and rubber be hauled in?

Here are my auto plants. The one on the left is the factory and the one on the right is the warehouse. now back to the question. What would sheets of glass and rubber be hauled in?

Why would you need coke and iron if you’re already bring in steel?

I meant to put steel as a result not an incoming load. Sorry.

In the 1950’s, tires & steel wheel hubs were produced in Akron. Shipments from Goodyear Tire & Rubber and Goodyear Wheel & Brake generally went in boxcars. Wood-line cars seemed to be preferred for tires. They were still warm & quite aromatic when the cars were loaded.

Probably the most popular routing was Akron Canton & Youngstown from Akron to Columbus Grove, Ohio, then Detroit Toledo & Ironton to Ford in the Detroit area. One story has it that the hot tires would be discolored by contact with steel, but they were OK if they contacted wood. I can’t verify that, but AC&Y did continue to use wood-sided cars in this service after most railroads had retired their cars. Presumably, AC&Y shipments to the Detroit area could also be routed AC&Y to New Washington, Ohio for PRR delivery; AC&Y to Spencer, Ohio to W&LE (NKP), then probably D&TS to Detroit; AC&Y to Sycamore, Ohio, then NYC to Detroit.

Appropriate AC&Y cars would be the Mather AC&Y “3000 series” boxcar kit from Sunshine; the Proto 2000 Mather boxcar (close enough for all but the most rabid accuracy hound); and the Kadee PS-1 which is scheduled to be released in a new road number within a month. Some 50-foot SS cars were obtained from (I think) MoPac and/or Frisco in the late 1950’s or early 1960’s, and MDC made a decent model, but they never released it in an AC&Y scheme. The first yellow billboard AC&Y boxcars were ex-NH early PS-1’s that first arrived in September, 1962.

B&O also served Goodyear in Akron. Presumably, shipments via B&O would be B&O mainline to Willard; B&O to Toledo, then probably D&TS to Detroit.

Possibly more info than you wanted.

Then you would be modeling a steel mill, not an auto plant. The models you have do not look remotely like a steel mill. The enormous facilies covering many square miles that others have talked about included steel mills as part of the overall huge property, but they were operated separately … steel mills as steel mills, auto plants as auto plants.

I know that you are using the ‘it is my layout’ justification for everything but I think this is so far from reality that it bears mentioning. Just my opinion, and you did ask.

Alex,

From reading your posts and the replies, it seems like there’s good advice being given.

Even though smaller buildings can be used to represent a much larger complex, perhaps they would serve better if backed up by more and larger building “flats” to give the impression of a much larger plant just “offstage” as it were. A low crossover bridge between two adjacent buildings that spans a couple of tracks can serve to mask the entrance to a hidden storage yard, someplace for the “incoming or outgoing” loads to go or come from. In fact, if you build background buildings just wide enough for those tracks the building itself will hide them. You can leave the “back” of the building open, hidden to your visitors. With that arrangement, you can “fiddle” with the loads and change them around between sessions. A boiler house, smokestack and coal pile would give your hoppers something to do out front. By “hiding” the main bulk of an industry, and using hidden storage tracks, you get the benefit of a large industry to generate traffic without the trouble and expense of actually having to build the blessed thing.

The buildings you have now are workable for early to mid 20th. century manufacturing plants, so keep the new ones and “flats” to the same style.

Have fun.

Lou

If you are interested in auto production and the buildings that housed it, google (discuss detroit old car factories) you’ll find a thread where people have been searching the Detroit metro area for old car facilities. There are plenty of pics and research on the buildings that housed the beginnings of automobile manufacturing in Detroit. As to modeling auto manufacturing plants, even the parts plants were huge. I model the auto industry and one of my factories is 20 feet long. I was going to model Buick City in Flint MI (bought all the Sanborn maps of the P.M. in Flint) but the main building would be 54 feet long. Hard to do even when selectively compressed. Hope this helps

Thanks everyone, especially Dr. Wayne and ACY, I am going to look for some wood boxcars to haul tires in (probably Accurail kits). So the last question is, what would glass be brought in by?

You sure have a lot of manufacturing ideas going on for those two little buildings. Maybe you could settle for plants that made specialty items for the auto industry and they did ship glass, in box cars.

Frank

Thanks for the info on glass Frank. I am going to keep the things the way they are, because I just like it. My layout is proto-lanced.