I have a really old CB&Q Tyco GP20 that belonged to my dad when he was a kid. I would like to get it running again because I also have a few other CB&Q locomotives and it would be cool if I could run all of them together. One day, it suddenly stopped working, which I am 80% sure is because the motor brushes wore out. Is there a cheap and easy way to fix the engine? Also, if I do manage to get it working again, how will I replace the old couplers with Kadee ones (the original couplers cannot be removed)? I have heard of people repowering it with the innards of another locomotive, such as an Athearn GP35, but how cheap is this? Am I better off getting another locomotive?

The really old (by that I assume made in USA, not Hong Kong) Tyco GP20 had a distinctive frame and motor arrangement, and the body shell was tailored to fit it (which causes some considerable non-prototypical elements around and in front of the cab for example, which you might want to take into account in deciding if the engine is worth reviving).

Thus it would not likely just sit down on a powered underframe from Athearn or LifeLike or Hobbytown without some modifications. And remember that the “really old” Athearn diesels had motors wide enough that Athearn had to widen their body shells to fit.

Your best bet might be to seek out another really old Tyco F9 or GP20 (which shared a similar frame and motor arrangement) that still runs well. Check to see if it is really really old (made in USA) or just old (made in Hong Kong).

The other option is to make it a dummy so it can still run with your other CB&Q locos.

There was an outfit, Yardbird, selling parts to older stuff but their website dated 2015 says the business is closed and remaining inventory is or was being sold on Ebay. But they kept the website alive for the parts list. No parts for this engine are listed.

Dave Nelson

Hobbytown of Boston makes a chassis which is a direct drop in for that body, listed as a GP9/GP20/GP30.

http://hobbytownofboston.com/?page_id=61

Rick Jesionowski

There are also a couple of pages Tyco GP20’s in Ebay.

Rick, that Hobbytown site looks interesting. It would be nice if they had some pictures or diagrams of the chassies, instead of hoping a particular shell will fit. I found the set that you linked to, and it’s $65.

Mike.

I don’t know if I would call this fix easy but I rebuilt a couple of Tyco GP20’s that have the “pancake motors”. I bought a bunch of motors off of E-bay and replaced the worn out motor in the truck.

And while I had everything torn apart I used new Atheran wheels sets modified to fit the Tyco truck.

The end result is a smooth running Tyco engine. Now the money part. You’ll need a lathe and a bench top mill to make the improvement.

Bernd

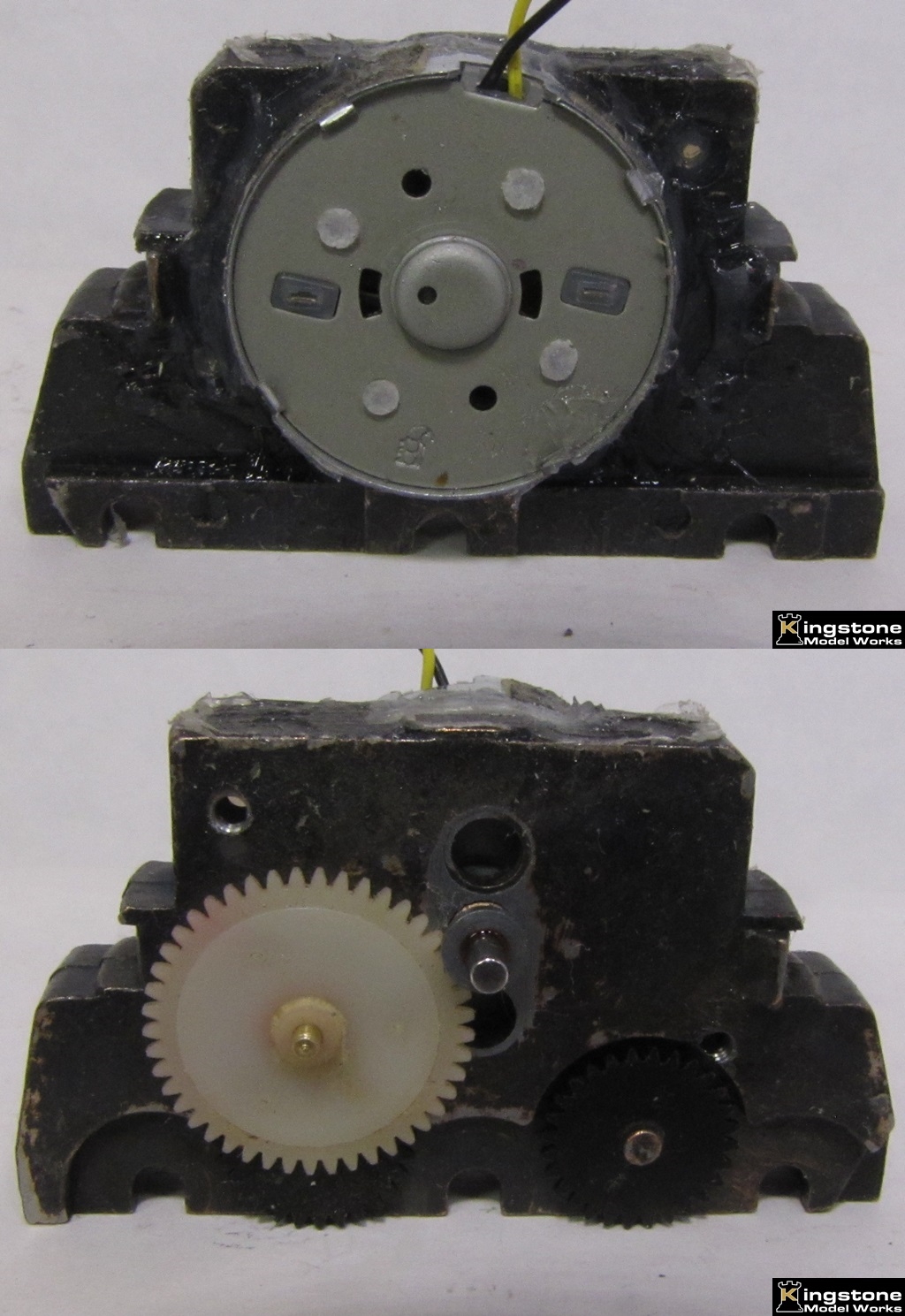

First off, How would I be able to dismantle the power truck? I have thoroughly looked it over and tried to pry pieces off, but it won’t come apart. Also, the motor looks totally different than the ones in your pictures. Here are some pictures of my engine.

HI there,

I have a US Made Cotton Belt GP20 which I fitted an Athearn BB GP9 chassis to and put a Mashima motor into it with Athearn Universals.

The loco was more sentimental like yourself with my parents having given it to me as my first scale item nearly 50 years ago! And yes it still performs OK and ventures out on the mainline fairly often. I model a loose Canadian theme but as I have seen pics of Southern Pacific units in Toronto, I can live with it!

Cheers from Australia

Trevor

www.xdford.freeasphost.net for your interest

Trevor, thanks for reminding me, but there was an article in Mainline Modeler magazine on repowering the Tyco GP20 with a frame and motor from Proto-Power West (A-Line) along with making modifications to the body to make it more realistic.

I checked their website and it seems they no longer offer the frame to make this conversion.

Rick Jesionowski

I believe my engine currently is fitted with a Mantua motor. At the moment, I have been able to remove the sideframes and motor brushes. Is there a way to replace the motor brushes? If not, will the body be compatible with a later Power Torque motor truck?

In from HOseeker.net.

http://hoseeker.net/assemblyexplosiontyco/tyco228gp20pg1.jpg

http://hoseeker.net/assemblyexplosiontyco/tyco228gp20pg2.jpg

If the links don’t work, go to hoseeker.net, click on liturature, scroll down to Tyco.

I’m not sure about brushes, if they availiable.

Like I mentioned in a previous post, there a few locos on Ebay, for reasonable prices, you can use for parts.

Did you check out the site Rick linked to? They have a complete powered chassie for $65.

Mike.

I have the super old Mantua-style motor on my engine. I was able to partially deconstruct the motor and take the mounting for the brushes off. They are these little carbon plates attached to brass rods. There does not seem to be very much wrong with them at a glance, other than that they appear to be rather worn. There is still a lot left of them, though. Also, the rotor (part where the brushes contact) appears to be covered with a blackish substance that is probably from the brushes. Do you think this would affect the conductivity going into the motor?

If it isn’t an issue with the brushes, what are some other reasons that my motor doesn’t work anymore?

UPDATE:

I seem to have gotten the motor working (for now) by cleaning the rotor and brushes. The next question is: How do I install Kadee couplers in the coupler pockets because it appears they are riveted together so I cannot open them.

Matthew

Well Mathew, now you’ve don it! [(-D] I just had to go deep into the archive tubberware containers and dig out mine. [(-D]

Everything on this loco is riveted, like it was not made to come apart. Even the way the truck side frames are attached. They are plastic, but when you gently try to remove them, the little tabs break right off.

I would probably grind of one side of the rivet off of the coupler box, and for reassembly, drill out the hole a little bigger, and replace it with a screw, or tap the hole in the truck base to accept a machine screw, like a 2-56. Hopefully, replacing the plastic horn/hook coupler with a metal Kadee won’t cause problems, as the coupler box is all metal.

Something else to look for, the front truck, with the motor attached, has plastic drive wheels on one side, and they have traction tires on them. It’s like little rubber “O” rings. Sometimes the wheels crack.

I noticed you can’t even seperate the motor from the truck, or remove the bottom truck cover with out grinding off rivets. It’s really something how they assembled these.

The body shell is nice, mine has metal railings that are very close to scale, and there’s even a little brass bell on the top.

When it was running, this was one of my favoite locos.

Evidently you’ve figured out how to remove the little board that holds the brushes in.

Good luck, I won’t stash mine away again, until you get things figured out, leaving it out for a quick refference.

Mike.

Hello all,

Glad to hear the update that you’ve gotten your vintage locomotive running.

An admirable reason for restoring this unit.

Albert Einstein was famous for saying, “The only way to get all the worms back in the can is to use a bigger can.”

This project might be in need of the “…bigger can.”

One thing that is most often overlooked, when beginning a project like this, is the expense of specialized tools.

Yes, you can replace the Hook & Horn type couplers with Kadees.

In addition to the tools needed to drill out the rivets you will need a coupler height gage to make sure the replacement coupler is at the correct height.

It appears that the couplers are mounted to the trucks. For more reliable operation you might consider body mounting the couplers.

To do this you will need to cut off the coupler pocket from the trucks and install draft gear boxes to the shell.

A tap set for 2/56 screws would be needed to body mount the draft gear boxes.

This might be a better option as opposed to trying to retrofit Kadees into the original draft gear boxes.

It also appears that this unit has traction tires on one side of the trucks with electrical pickups on the opposite side.

New traction tires are readily available from aftermarket sources, but the problem with electrical pickup on only one side of each truck might cause operating problems; especially if you decide to convert from DC to DCC.

North West Short Line makes Stanton drive motors; the motor is incorporated into the trucks, in addition to a plethora of remotering supplies.

The advantage of using a Stanton drive motor is that you don’t have to worry about replacing the gear towers along

Both Tyco and Life Like products have potential to be kitbashed into something more protypical if you want an accurate looking locomotive or caboose.

From the item description: “this unit runs slow and I recommend it only for parts”.

If he repowers with one Stanton drive he will be lucky to get the locomotive to pull more than a few cars. If he repowers with two he’ll be right at $170 plus shipping … and then have to make all the modifications to fit them. That seems a steep price to get rid of gear towers.

Wonder how often the Hobbytown ‘bespoke’ chassis (or an engine containing one) shows up on the 'Bay?

I’m old enough to have had a Tyco GP20, instead I still have my B&O F7. I haven’t even tested it on a DC track I have since I got back into MR 3 or 4 years ago.

At the time I thought it was poorly detailed and it hasn’t improved with age. I keep it only because I inherited the Pack Rat gene. I am not attached to it and hope my kids don’t spend any money on it.

Nwot my Steward undec. F3 that I painted 25 years ago and never finished detailing, got a DCC decoder this weekend, glazing and handgrabs last week. I hope they keep that one.

Yep, Henry the Stewart is many steps above the the Mantua/Tyco that the OP has.

My thought is, he puts it all back together, knowing that it’s running, and displays it, in honor of his dad.

I could go on in detail how this shell fits perfectly on an Athearn GP35, but I’ll wait until he respondes.

Mike.

Bernd, I seen your post about your rebuild in MRH. The loco that the OP has, and I have, does not have the typical “pancake” motor. It’s part of the power truck, sits parellel to the truck, and has the worm gear on each end of the shaft to power the truck gears.

Mike.

Hello again,

Is there anywhere I can purchase replacement brushes for my engine? I’ve been able to find power torque brushes, but not for the old Mantua motor.

Also, if my engine fails again, would the shell fit the chassis of a newer Mantua GP20? They still produce them, but I’d assume the current design is quite different from the old ones.