An irregular series on construction of a HO bandsaw mill kit from Keystone Locomotive Works:

Now we’re getting to the fun part.

I am making several alterations to the construction sequence as I get to the roof. First, I want the entire roof to be removable for later maintenance or adding more details to the interior. Second, I want to have some portions of the roof made from clear plexiglass to allow viewing of the interior without disturbing the structure. I had done this with Keystone’s Planing Mill kit (to which I added an interior), and it worked well. Third, I had purchased an electronic sound-generating unit from Innovative Train Technology (ITTC) and wanted to add that into the structure. The sound unit makes the noise of a high-speed blade sawing through a large log or timber.

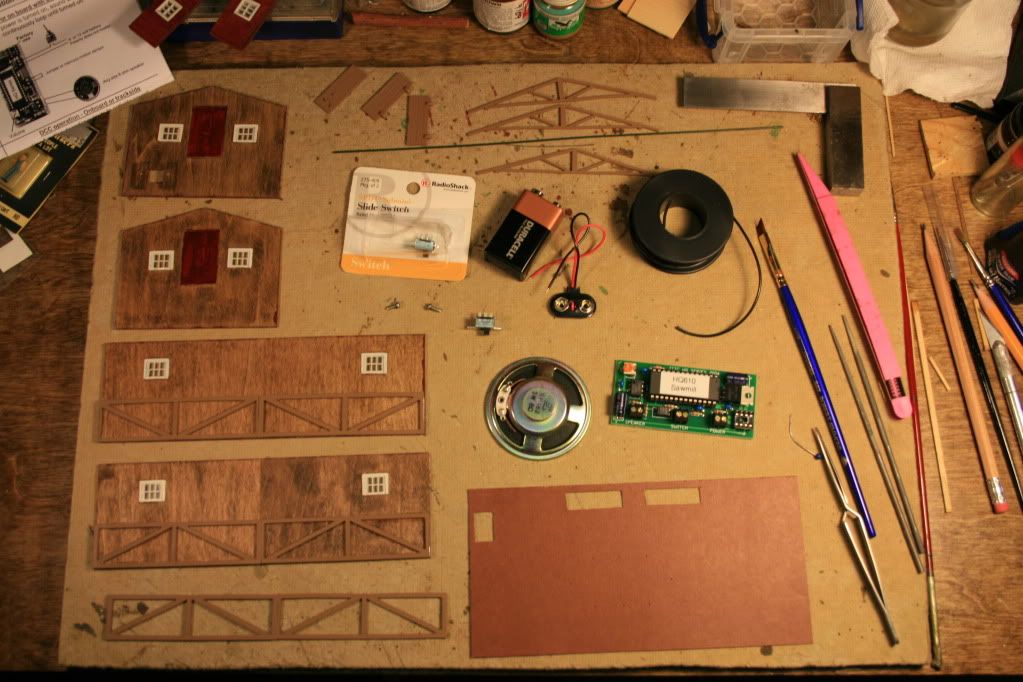

My initial thought was to put the sound unit within the otherwise unoccupied first floor of the mill, but then there would be troubles stringing the speaker wires to the removable roof area. The saw filing room sits directly above where the bandsaws are located. There is a sort of false floor to the saw filing room, raising it an additional six scale feet above the main beams of the mill. It would be a tight fit, but I decided to try to put the sound unit within that space, so that the speaker would then be almost directly above the bandsaws. Here’s the components involved:

And then here’s a photo of the underside of the saw filing room with the sound components installed. The “trap door” to allow access to the battery is made from a piece of tough, translucent plastic that was once part of the packaging for a copier ink cartridge at work. It had gone into the scratchbuilding box on the premise of “that might be useful someday.” Two small cable ties form the hinges, and two