Now about Campbell, they have always used sugar pine and northeastern uses a slightly softer wood, I think yellow pine.

I always thought nothing looks more like wood than wood, but I have seen some pretty convincing work done that made it hard believe it was styrene, not wood. Styrene is easier to work with.

I still use wood, mainly since I have about 2x lifetime supply, way more than enough to finish out my planned structures and a ton of little sheds, outbuildings, crates, etc. Also, I don’t have the techniques down that makes styrene look like wood, although I need to learn it, and I will, for flatcar decks. Dan

Mel, thanks for those links. Your work is inspirational.

Back when I was in N scale in the 1980s to the early 1990s I did a lot of scratchbuilding because almost everything available was European prototype style structures.

Unfortunately, this old snapshot from the 1980s is way out of focus, but I scratchbuilt most of these buildings for my first layout.

All the vehicles were European models.

-Kevin

I store all my strip wood in 8" long pieces of 1/2" CPVC pipe with the size written on the side of the pipes. I toss them in a bin when I do not need them.

So far, I have not needed a piece of stripwood longer than 8" for any of my projects!

I use plastic when the structure os going to look neat, well maintained, and painted.

When I am building a heavily weathered or stained/unpainted structure, I prefer to use wood as the building material.

Thank you for that useful list. Those are the sizes I will order in bulk.

That sounds a lot like my plans. Small buildings really make a scene.

-Kevin

I’ve built a lot of small structures using plastic, and all were done in a manner so that they looked well-maintained, even if they were very plain in appearance…

…and a number of these hose & hydrant sheds…

This coal dealer’s structure was built mostly using styrene shapes for the steel work, sheet material for the bins, and Campbell’s corrugated aluminum siding for the roof and sheathing…

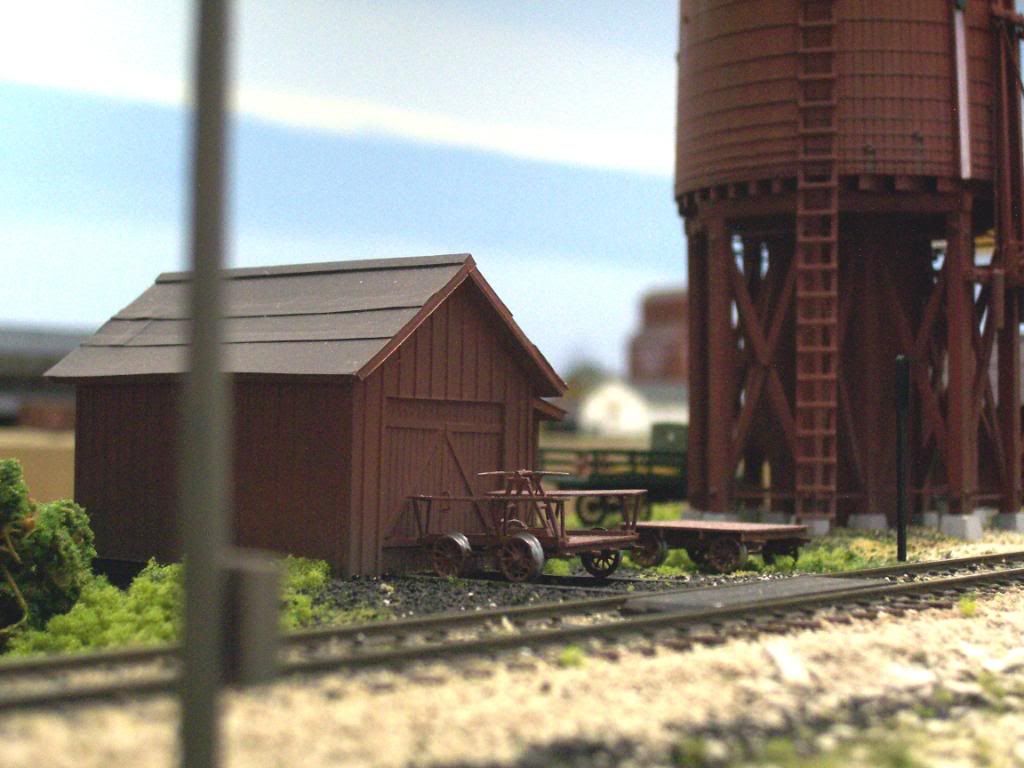

For the slightly larger structures, in this case mostly railroad-owned, there’s usually a few more details, and a paint scheme adhering to company standards…

I scratchbuilt, (except for the doors and windows) a couple of

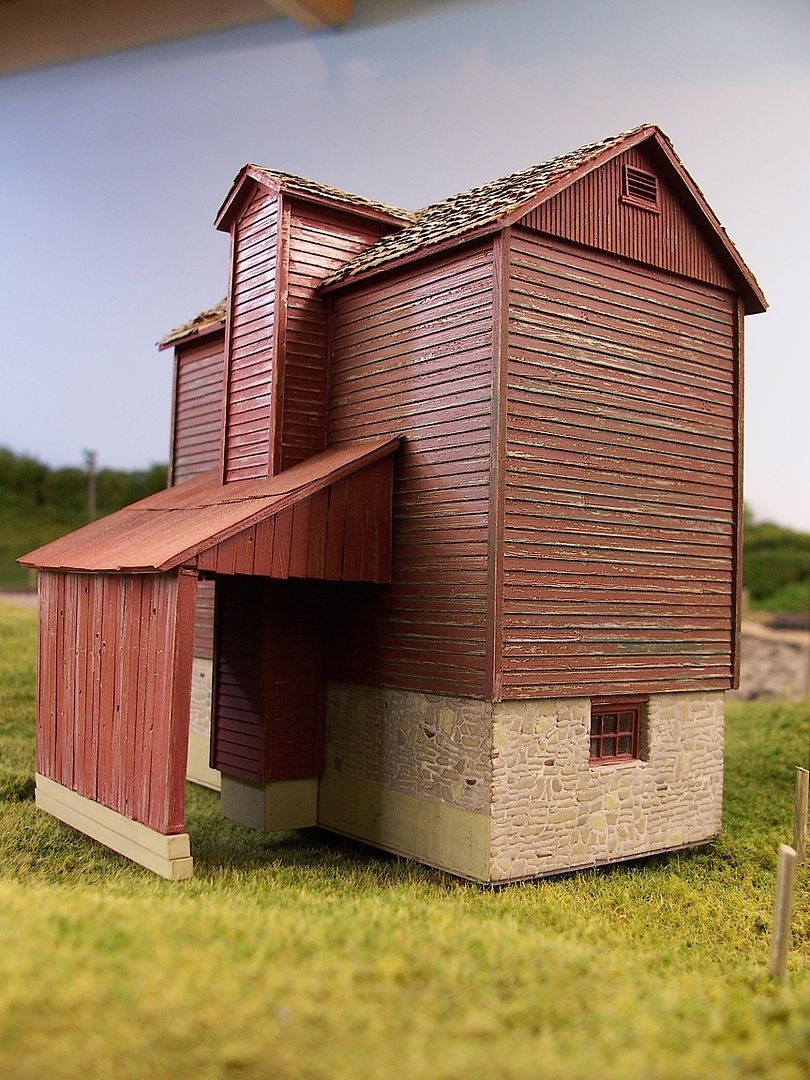

These pictures are ones that I thought to be most demonstrative…this elevator may have been used for grain, or perhaps coal, but it’s likely going to be an abandonned building, once I have a permanent spot for it on the upper level of my layout. Other than the Campbell shingles, everything else is styrene…

…and these styrene “planks” are my first attempt at making styrene look like used wood. I think that creating creosoted “wood” for a planned trestle should be much easier, and more realistic, too…

I think this one, below, is closer to the other end of the scratchbuilding-with-styrene spectrum…

…other than the windows, which were left-overs from a couple of Walthers’ kits, and some structural styrene for the butterfly sheds, this combination station and post office is nothing but .060" sheet styrene, cut-out and scribed with a utility knife, and painted by airbrush,

Wayne, I don’t think anyone will complain about the photos of your amazing work.

I am using N Scale, and I scratch build most of my structures from styrene.

I’m commenting because the last structure you show has so many windows. Windows are the worst part of scratchbuilding for me. It’s the cutting the openings that takes me so long and is difficult for me.

Great work.

I agree. Excellent modelling by Wayne.

David

Those styrene planks are amazing. Worthy of an article on how you did it,

Ray

Kevin,

In 1890, or 1910, most clapboard buildings would have had a siding exposure of 4" to 6" max, or about .069" max for HO scale.

By the late 1920’s as housing styles changed, exposures increased into the 7" to 8" range.

Craftsman and Colonial Revival styles of the first half of the 20th Century would have been mostly the larger 7" to 8" exposures, but other styles of houses were still built using the smaller exposures.

Modern vinyl siding is often sized to simulate older styles of siding and is often around 5" exposure, but 8" exposure products do exist.

In my view, as a trained architectural design professional, and a restoration consultant, 1/8" is way too big for HO siding. 1/16’ would be a better general size for HO, scaling out to about 5-1/2".

As for the current products available, I have not kept up. I guess when I get to that on the new layout, I will be searching too.

Sheldon

I love seeing pictures of your layout.

-Kevin

Me too. That is why I have no plans to scratchbuild any large structures.

I agree.

THANK YOU!

This is exactly what I needed to know about clapboard construction. We have no clapboard buildings down here, just a few with vinyl siding.

A appreciate the time you took to write this description for me.

-Kevin

I understand about lifetime supply- I bought a bunch of stripwood in a deal and I am not sure if I will ever use it all- but I have a stamp mill that is on my to-do list that should exhaust a good portion of it. I organize it in a 5 gallon bucket that has a insert below to keep things straight- I drilled holes in the lid with a paddle bit. (It the midst of this operation our younger son about 12 at the time walks out sees me doing this turns around and announces to my wife “Dad’s lost it- he’s drilling holes in a bucket”) I did a similar 2 gallon bucket to do evergreen styrene strips. I leave them in their original sleaves.

I think that Atlantic Central’s accessment is pretty close. Sometimes you have to look at what you are modeling too to compare. I am a little divided as to which is better to use for clapboard styrene or wood. I have both and if I am going for a better maintained look I use the styrene- more weathered I use the wood- Northwestern makes a neat more weatered/ distressed clapboard too. This street is a mix of the two. The tan storefront and the white hotel on the end are styrene. The slanted roof duplex in between them is wood. (The brick Gilpin hotel and the one next to it are kitbashes) Styrene tends to be a bit stronger for low relief buildings. Sometimes for me it is a mood issue- what do I feel like working with? As an aside you never know what strange scratchbuilding supplies you will find- the stations “stone” is textured scrapbooking paper.

Good point about the look/texture. When new and painted, or even just well maintained for 100 years, clapboard siding is perfectly smooth.

In our business, we hate the fake woodgrain look on anything and strongly discourage our customers from such products.

Cedar shingles are about the only traditional building material intended to show some grain, and in fact even those are baby butt smooth in the versions used for decorative fancy cut painted treatments on Victorian era homes.

Sheldon

Used Northeastern Scale Lumber Products to construct my HO cannery/wharf scene, including 1/16" spaced clapboard siding.

Regards, Peter

As always, Peter, amazingly realistic work! You, Wayne, and several others on this forum are an inspiration to us amateurs to keep working on improving our skills.

Thanks for the kind words John, much appreciated.

A note on styrene lumber: The late Harold Minkwitz’s website is still up and contains a wealth of info. about making styrene look like wood. www.pacificcoastairlinerr.com

Regards, Peter

I use the exact same approach with wood and styrene for scratchbuilding. Thank you for all of your input.

When I (“finally”) build my backyard caboose/shed, I am going to use an engineered product that looks like wood for the entire extrerior. This is supposed to be more durable and able to withstands tropical storms.

Wow… now that is the look I will be going for with my wooden scratch-builds.

Thanks for the link Peter. That was full of great information.

-Kevin

Kevin, what does "looks like wood " mean? We use Azek and other brands of PVC “lumber” all the time. Once it is painted it looks like wood. Because finished wood siding and trim is perfectly smooth and so is PVC trim.

Molded in wood grain is what looks fake. I am repainting a 120 year old house right now, with largely its original trim and siding, I can’t see any wood grain, and you can’t tell the places where we have used modern PVC lumber on this house from the original materials.

I will post some pictures later.

We build all sorts of traditional detailed porches, siding and trim from modern synthetics all the time. Looks just like wood when we are done. No fake wood grain.

Sheldon

Here are some photos of the 1904 house we are currently working on. We are doing minor repairs and repainting. We have been working on this house off and on since 1999. Originally we did a major restoration but the home owners did some of the work themselves.

So, do you see any wood grain? Tell me what items on the exterior are original, what has been replaced with wood, and what has been replaced with PVC lumber?

.jpg)

Sheldon