Hello in the summer heat ![]()

I have always had a desire for a special locomotive for my freelanced switching layout.

It all started when I read about the small port terminals in New York and the locomotives they were using.

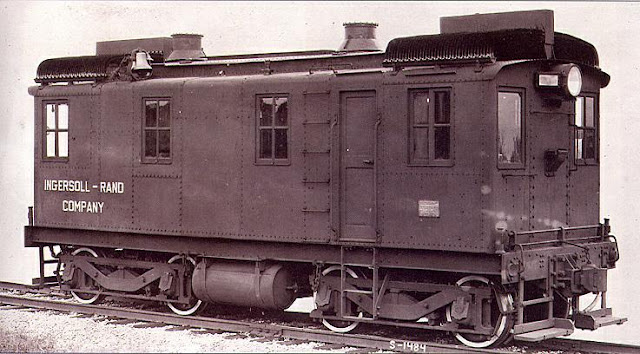

Central of New Jersey had an Ingersoll Rand locomotive that is one of the first commercially made diesel locomotives:

A very beautiful locomotives in my opinion ![]()

Then came Tim Warris with his Bronx Terminal in HO (an incredible layout).

There he showed how to take a brass Boxcab and rebuild the drive to get it to run as well as it looks.

The problem with just Boxcabs is that the only models that are available are either made of brass and costs a fortune, and runs like a bag of s**t.

Or you may have to be be content with an old Roundhouse locomotives in plastic that is also going like muck … Plus, you have to add the extra detailing to make it look reasonably good …

Neither option was very good ![]()

I thought it would be nice to build one myself.

One problem was that it was really tricky to get hold of the drawings of the locomotive.

Luckily, as I am a member on a U.S. forum, where one of the members have recently built an I-R Boxcab in brass and in S-scale.

I emailed him about the drawings and he emailed me back everything he had as PDFs ![]()

There was a rather prominent model railroader (was it Dean Freytag? I don’t remember), who came to a clinic with a very nicely constructed bridge. He showed the bridge to the audience, pointed out the model’s shortcomings, and then smashed the bridge to splinters, all to make the point that a modeler has to be willing to toss a project and be willing to start over if said project is not turning out right. To be willing to do this is probably more important for someone trying out some new skills.

I look forward to seeing photos of the painted model. Those ancient I-R diesels were pretty interesting.

Excellent work!!! I can’t wait to see the finished painted model. The 70 tonner is a good choice for the donor power unit.

[bow] [bow] [bow]

Excellent job! I was a bit sceptical about using .050 styrene for walls as it has a tendency to warp over time, but I hope for you that with your "sandwich construction it will hold up. I liked your “boiling water” technique.

As a fellow scratch builder, the thing I always hated the most was and is, adding rivets! Archer Fine Transfers makes scale cast resin decals of rivets, louvers and treadplate. They are cast/printed on Microscale’s Thin Film. They are applied before painting and the film completely dissapears, leaving just the 3-D rivets. Having used all 3 products on several models, I can highly recommend them. Here’s a shot of the 5/8" rivets on a handrail stantion:

Very impressive work, and a great description of what you did and how it was done. Thanks for sharing.

Jim

Great job Graffen, I too like those boxcabs. I went a different route with the MDC shell on a Spectrum 44 ton chassis. Less detail yes but a great runner.

Nice work Graffen. Scratch building is fun to do…and to watch!

Tom

Great work Graffen! Thanks for sharing and for the inspiration.

Dave

Thanks all [:D], I will look at the rivet decals for sure!

I have painted it now:

Not really finished yet, a few windows to finish and so… ![]()