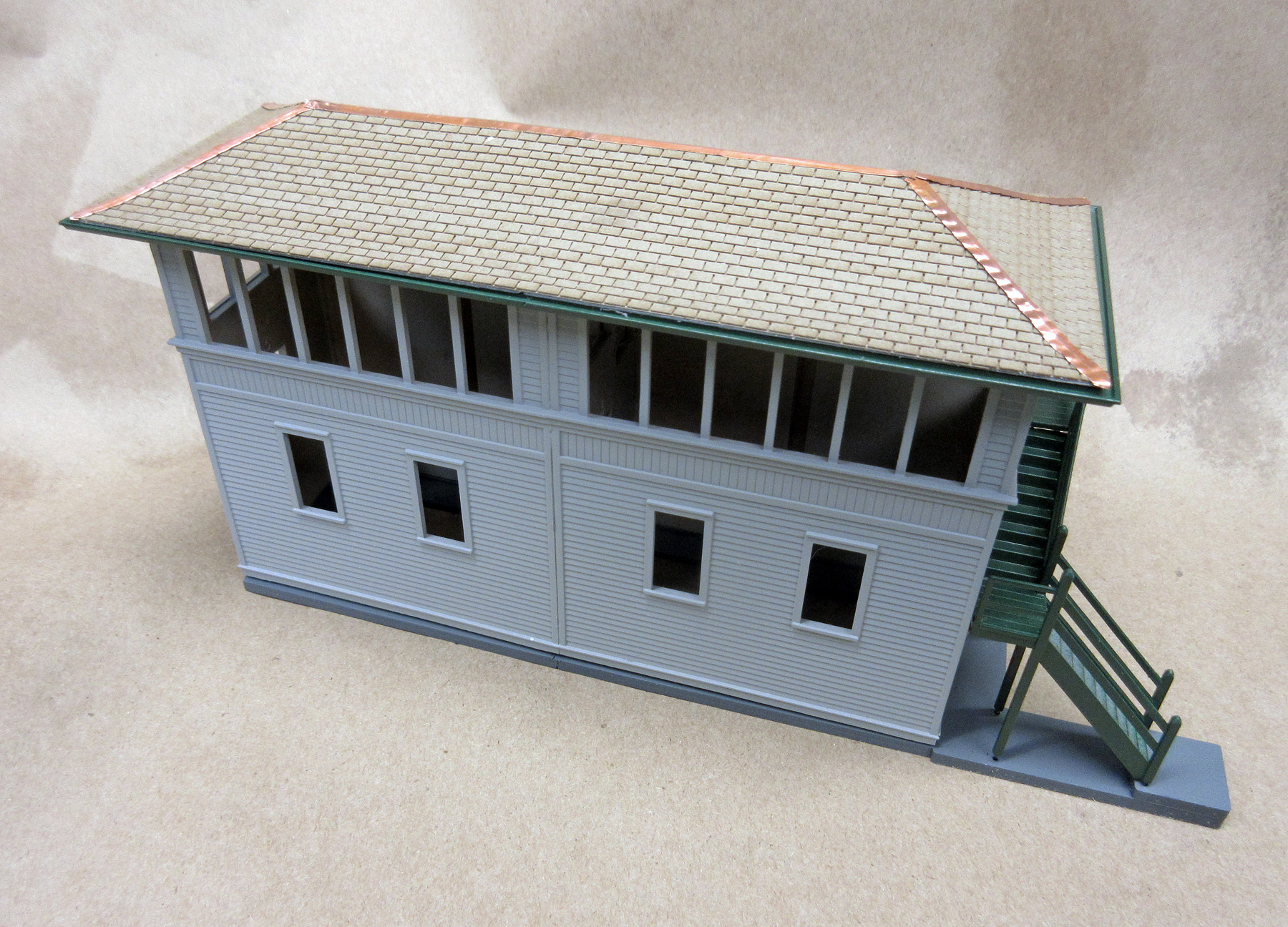

I’m building a craftsman kit and I’ve come to the roof. Eyeing the roll of shingles supplied in the box – I guess they’re really supposed to be wood shakes – I wondered if there isn’t a way to make shakes that look slightly more real. Those supplied are nice, and easy to apply – just moisten and stick on! – and I don’t mean to throw shade on the genius that enabled Durange Press and Campbell and any number of other manufacturers to approximate shake roofing for their kits, but real shakes would be just a bit thicker wouldn’t they? And even though real shakes are irregular I think they’re not so wavy. It’s always bothered me a little.

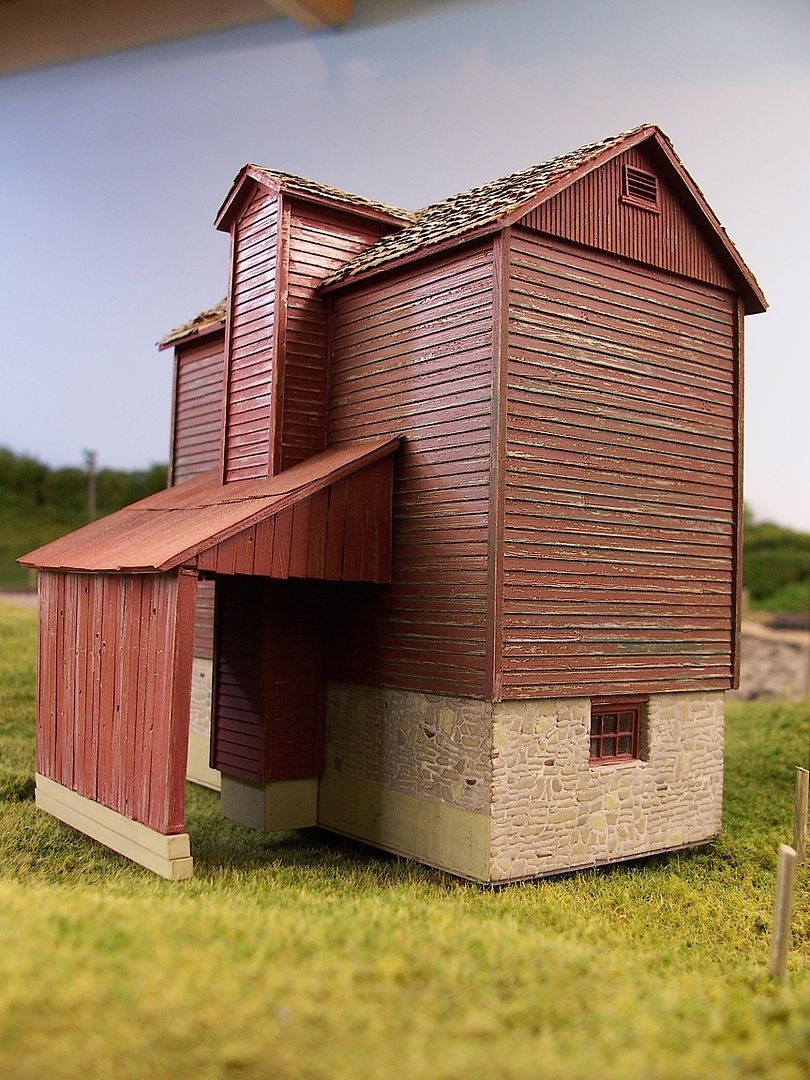

I experimented by cutting some strips from a grocery bag and slicing the edges to make individual shakes. Here for comparison is a photo of the experiment alongside the roof of a general store I scratchbuilt when I was a kid, apparently using a spare roll of Campbell’s shakes.

I’m not sure my new idea represents any improvement at all, especially since the old roof was so nicely weathered (how did I do that?) and has gathered the dust and damage of four and a half decades.

I’m not yet decided, but I’m leaning toward the easy roll. This kit is already taxing my eyesight, neck muscles and the free time I have available for the hobby. I give myself high marks for innovation and sheer pluck, but I may not use the paper bag. I might try again sometime with a card stock a bit thicker than the bag.

Happy Thanksgiving everyone, if you celebrate the day.

-Matt

.JPG)