Recently I was looking at photos of steam engines and noticed some of them had a large horizontal tank located on top of the boiler behind the bell and in front of the smoke stack.

I was wondering what purpose this tank served

Recently I was looking at photos of steam engines and noticed some of them had a large horizontal tank located on top of the boiler behind the bell and in front of the smoke stack.

I was wondering what purpose this tank served

Hello,

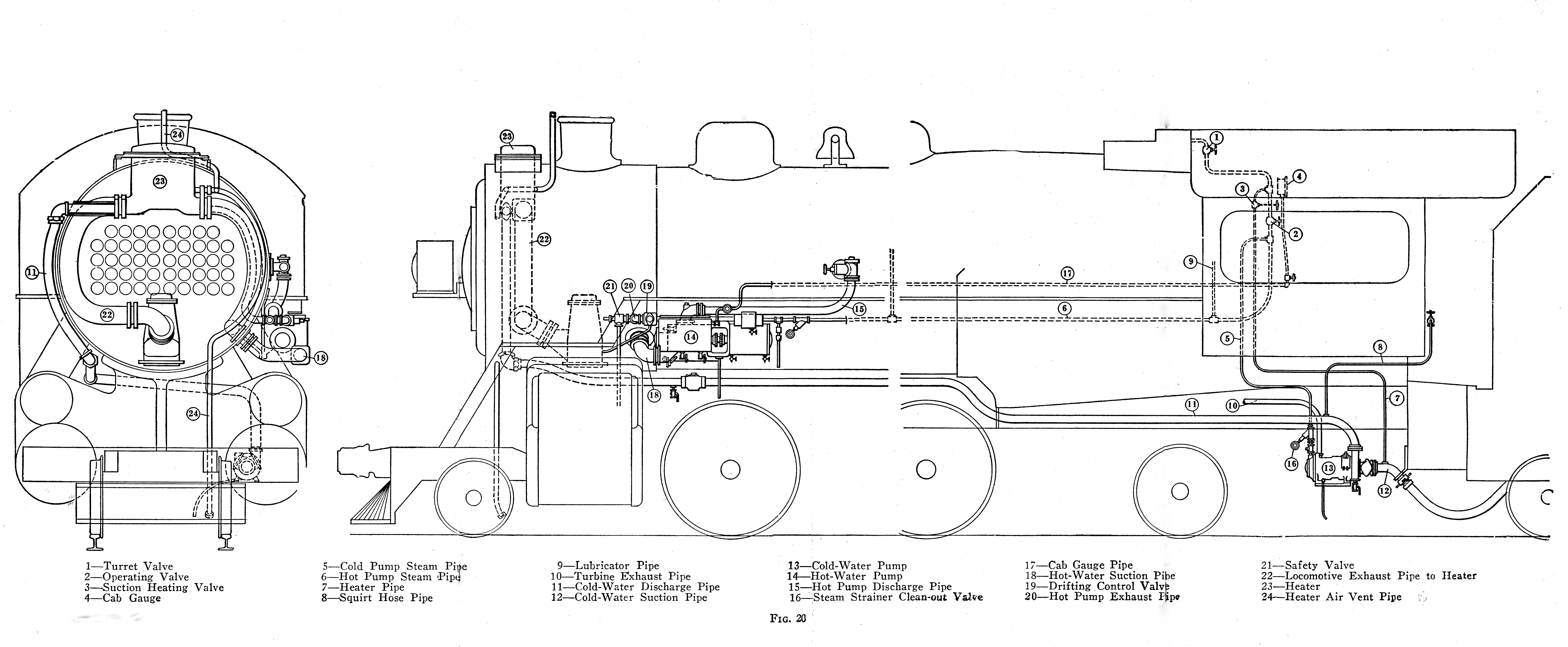

That tank served as a heat exchanger as part of the boiler feed water heater. It had a series of smaller tubes which were surrounded by exhaust steam diverted from the steam chest.

Rather than throw away useable heat the cold water from the tender could be pre-heated, thus increasing efficiency and reducing fuel consumption in converting the water to steam.

That condensed, exhaust steam was also returned to the tender to further increase efficiency.

The most notable (visually) being the Elesco but there was Worthington, Coffin and others of varying designs. Each of those manufacturers having various types themselves.

Elesco1_zpsdfejh59s by Edmund, on Flickr

Elesco1_zpsdfejh59s by Edmund, on Flickr

Good Luck, Ed

Hi Ed,

I knew what the tanks were for but I wasn’t sure how they worked. Thanks for the information.

The complexity of steam engines never fails to amaze me.

Dave

Those tanks are called “feedwater heaters”, and they are not really tanks.

They function exactly the same as heat exchangers on marine diesel engines, and the design is very similar. It is easier to find pictures of marine diesel heat exchangers than feedwater heaters.

-Kevin

Thanks for your helpful and prompt reply. I was guessing that it might have something to do with heat exchange. Now I know

I was trying to simplify the terminology. I did mention that they were “heat exchangers” though. Technically, the outer casing could be considered a type of “tank” although the liquids passed through them rather than get stored.

I suppose, in hindsight, I should have said “Tank-Like”.

The Coffin design had the tube bundle shaped like a saddle and could be contained within the smokebox or suspended in front of it. The Worthington type BL had a heater which was integral with the pump and was a rather large affair usually mounted on the side of the engine.

Here’s a look at the Worthington type S.

Worthington_S by Edmund, on Flickr

Worthington_S by Edmund, on Flickr

A slightly different arrangement to accomplish the same goal.

I agree, Dave. It is fascinating to study each system that is applied to locomotives and how they interact with each other. In later years — as boiler sizes increased — it became a challenge to fit all of these devices on to the machine without compromising clearances and/or accessability.

Thank you,

Cheers, Ed

Hi Ed… I was responding to the OP, not you. I was trying to offer another term to search for that might have easier to understand information that would answer how they worked. It is simple to find cut-aways and flow diagrams for marine diesel heat exchangers. That could help with the understanding of how the feedwater heater on a steam locomotive does its job of heating incoming water with heat energy that would otherwise be rejected to the atmosphere.

I know I never really understood how a feedwater heater worked until I took a heat exchanger apart… Eureka!

But I sure loved all that plumbing even if I did not understand the purpose of it all.

-Kevin

Hi, Kevin,

I see what you mean, good call [Y]

I’ve taken apart a few heat exchangers in my time as well. Some we had were packed full of a rusty sludge and one day I got the [I][8D] to collect all that sludge and bake it dry, sift it through some fine-mesh screen and make up my own “Rust-0-Magic” weathering powder [Y].

We had to resort to some twenty-ton chain falls to pry the tube bundle from out of the casing! Some days I miss all that fun [:-^]

Regards, Ed