Hello all, I am returning to the hobby after a hiatus of a few years, and am planning for a new layout representing the Boston & Maine Railroad’s Connecticut River Line. My layout plan has a freeform double-deck peninsula, including some curves that seem awkward to do with L-girder or grid benchwork. I was thinking of installing a curving stud wall to support the peninsula. I got the idea from Bill Boyd’s Kearney & Black Hills RR shown in the May 2005 MR. I would really appreciate it if someone could help me understand the process and answer a few questions: First question: Is it possible to build a less than full height steel stud wall? Normally, tracks are installed on both the ceiling and the floor prior to building the wall, giving the wall its rigidity. Unfortunately, my unfinished basement has lots of ductwork that sits below the ceiling joists, meaning that I can’t install a track on the ceiling. Is there a way to build the wall so that it doesn’t touch the ceiling, and the upper track is installed after the vertical studs are mounted? Thanks in advance! [edit] I’m not sure why the line breaks are getting deleted. Hopefully someone is able to parse my post and still help me out.

Steel studs can be cut to any height. You can frame down the channel with wood.

But, I can’t imagine anything being easier than wood for a curved layout. You can cut the L-girders to any shape for your edge.

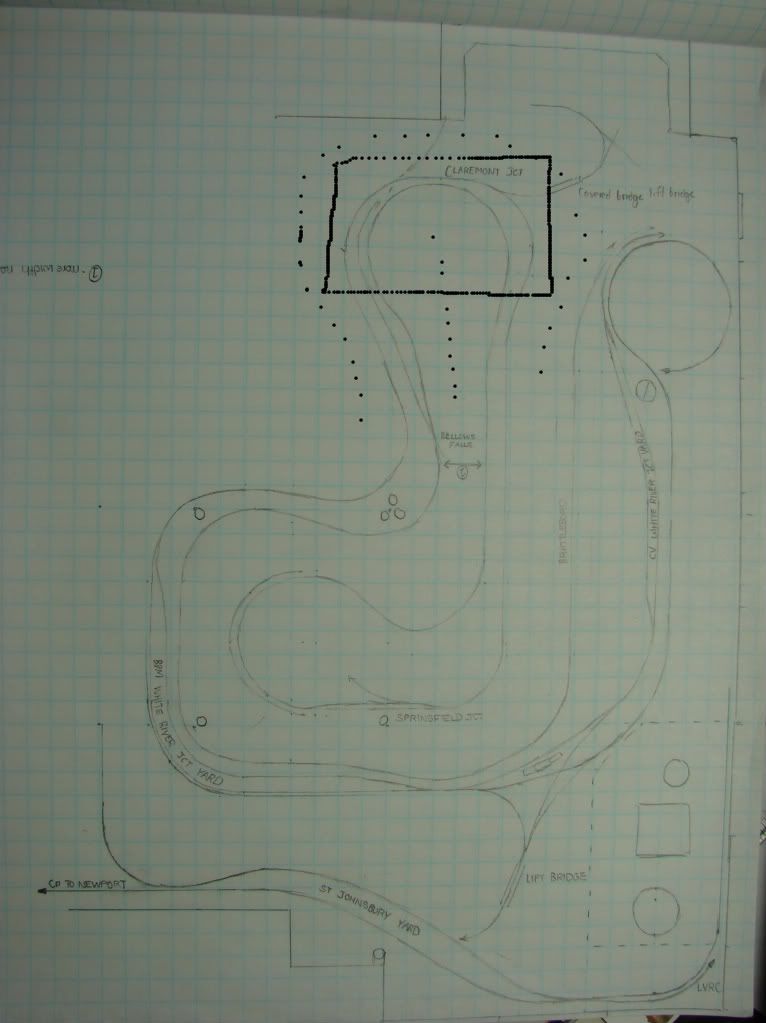

Spacemouse, I really like the idea of framing it with wood. The area inside the black box is the spot causing the largest problem with L-girder. The peninsula, viewed from both sides with a backdrop and support for the upper deck in the middle, makes a 180-degree turn. The widely-spaced dots indicate aisles. Is there a way I could do that in a straightforward way with wood?  Timboy, I don’t have a jackhammer, unfortunately. What were you thinking of doing, though? Thanks

Timboy, I don’t have a jackhammer, unfortunately. What were you thinking of doing, though? Thanks

Yoshi, there’s a simple way to do it with L (or steel stud ‘C acts like L’) girders. Just put one parallel to each aisle edge, including the two edges of the in-peninsula pop-up zone. Then use discontinuous joists across that zone. The stub L-girders won’t even need separate legs if the continuous joists across both ends of the zone are strong enough to support them from above without sagging.

I build ALL of my benchwork with steel studs - ‘C’ girders, legs [EDIT - standing on the concrete floor, not imbedded in it], diagonal braces, joists, even risers. The only wood I use is cookie-cut plywood subgrade under my foam roadbed. All you need to do is think outside of the rectangle. There’s no law that says that L girders have to be parallel to each other, or to anything else. Joists likewise. Just leave them a little long, then cut them off where you decide the fascia line is going to be.

My original ‘one stall of a two car garage’ layout in my present space had a 7 foot steel stud wall incorporated as part of its support/enclosure structure. The studs on 16 inch centers were a major PITA when it came to accessibility, both above and below track level. Happily, I was granted full use of both stalls. That wall was the first thing to go. (The studs have since been recycled as joists, risers and cassettes.)

Chuck (Modeling Central Japan in September, 1964 - on steel stud benchwork)

Steel stud walls in a building are usually not anchored to the ceiling. They can be built to any height but you will have to do some kind of cross brasing for support and strength. Steel is pretty EZ to work with if you have an abrasive blade chop saw, tin snips and self tapping sheet metal screws.

Me and 2 other guys studded up a 2500sq.’ doctors office in 1.5 days.

Go find a building where a sheet rock crew if putting walls up and you’ll see how EZ it really is.

Thank you all for your replies! TomikawaTT, I like the path you have suggested - it does seem possible now to build this fairly easily with the L-girder. At the same time, I like the simplicity and speed possible with a steel stud wall, especially when its down the center of the peninsula and hopefully won’t interfere with access - Loathar, would even Masonite hardboard be a sufficient cross-brace?

Should work. Depends on how much weight you want to put on it. This might give you a good idea. They went to the ceiling line, but you can make them as tall as needed.

I recently tore down a free standing Metal Stud / wood hybrid set of benchwork.

One thing that I did not like from my experience was the “bounce”. There was a lot more flex in the steel than in wood, and over time it grew annoying.

I expect that were my benchwork completed, some of it might disappear.

I also expect that the bounce would be removed mostly by tying it into a solid structure (wall or ceiling), however when I used the remainder of my steel stud supply to frame an actual wall in a home this past spring, it too exhibited a fair amount of bounce - even securely anchored above and too existing walls, it just feels less solid than a lumber framed wall.

Are they easy to erect? Sure are. Materials are also about twice that of good lumber, so that’s something to consider as well.

Here’s some shots of my bench work being taken down

Railroadyoshi, if you are going to have 2 levels at this point, the rigidity of the entire system should be enough that the curved wall needn’t be floor to ceiling. Just make sure all the connections are very secure. You might want to consider doing some bolting or perhaps even welding. Bob T