So, what size(s) should I stock up on to provide added bracing for plastic structure kits? That seems to be the one detail missing from the “use scraps of styrene to brace the walls” articles. Anything that’s stiff enough and fits?

–Randy

So, what size(s) should I stock up on to provide added bracing for plastic structure kits? That seems to be the one detail missing from the “use scraps of styrene to brace the walls” articles. Anything that’s stiff enough and fits?

–Randy

Most of the time I use wood. To get the same strength in plastic, it has to be larger than if wood is used.

Don’t forget the magic of Lego’s:

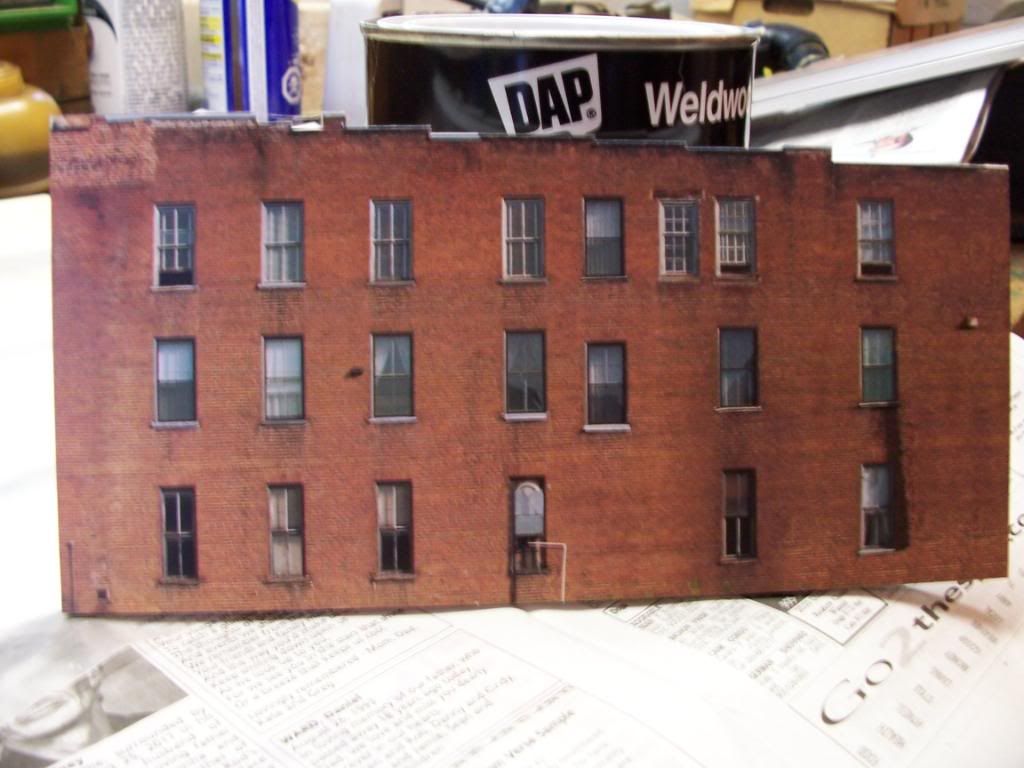

[That’s an N-scale building from DPM walls]

They’re plastic and CA easily in place, plus they’re a perfect 90 degree angle!

Just ask your kids before you use them ![]()

I’m afraid to use my legos, they are so old as to probably be classified as ‘vintage’.

–Randy

I bought a whole bag of Legos really cheap on e-bay for this very use.

Steve

Don’t forget the magic of plastic household products you toss into the recycling bin on a regular basis. TicTac boxes, dental floss containers, the small bottles of shampoo you get in hotels, are just examples of packaging thatall feature perfect 90 degree angles that can be used.

Dave Nelson

At A.C. Moore or Michaels, a couple of dollars buys a lot. I pick up strips of balsa wood, 3/16 or 1/4 square, and put them around the edges. Then I add interior floors with 3/16 foamboard.

I like interiors in my buildings, but this technique provides a solid structure even if you don’t add lights or anything else.

Hi Randy!

You are exactly right! “Anything that’s stiff enough and fits”.

I use any scraps of styrene I have laying around to reinforce styrene structures. For corners, if it can be cut into a 90 degree angle it can be used as a brace. I don’t think the thickness of the brace matters too much unless the structure will be put under load, like a bascule bridge for example.

If you are going to purchase styrene for reinforcing purposes all you really need is flat stock that you can cut to size. To make it easy to cut strips, I purchase sheets of styrene with lines already molded in. This is one example of many choices offered by Evergreen:

http://www.walthers.com/exec/productinfo/269-4060

The above sheet is .040" thick so it will provide plenty of support. When I need a piece, I just choose the width and score along the molded line. Snap. Cut to length. Bingo!! If you need to make “I” beams just cut the appropriate strips and glue together.

The spacing of the V grooves is entirely optional for bracing purposes, but you might find that a certain spacing makes the sheet usable for other things that suit your purposes too.

Dave

For wood I would go with basswood over balsa, it is stronger so you could use smaller pieces like 1/8" square

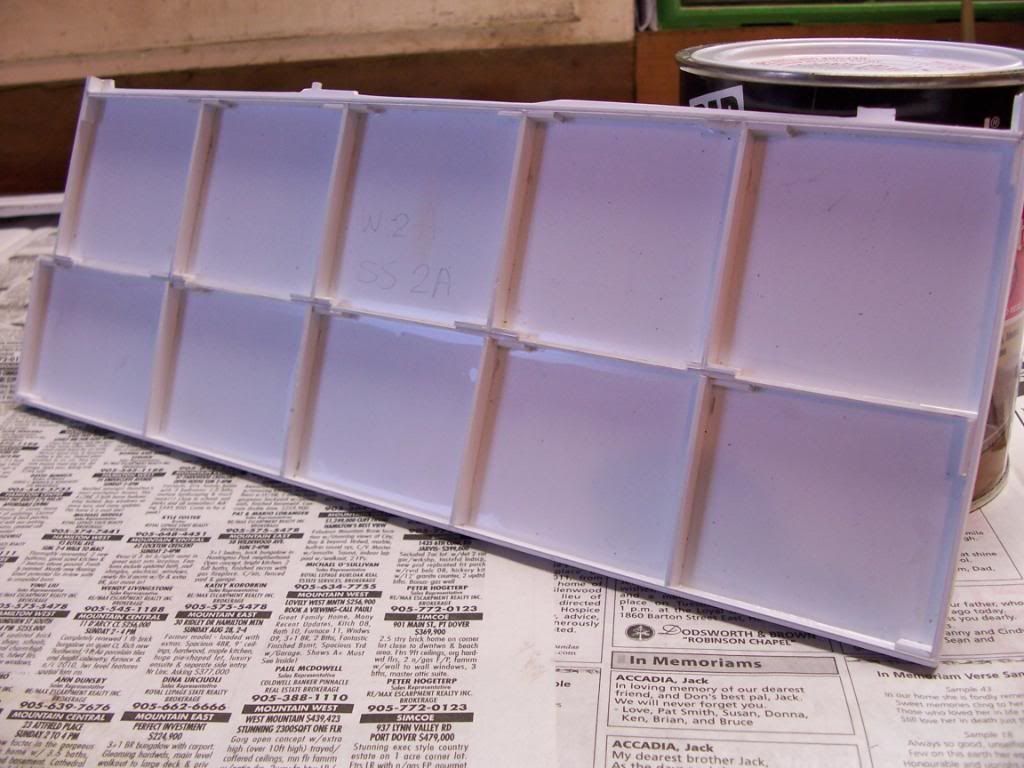

With styrene, it depends on the size of the structure. For small ones like 2-story DPM buildings, I would go with scale 6x6 or 6x12. For larger structures, I use Plastruct I-beams or 1/4" square styrene. This is Sheepscot Transfer and Storage, made from DPM modulars, that I made a few years ago. You can see the internal bracing I added using Plastruct beams

As you can see, it is a good sized building and is very stiff with the added bracing. Modulars are not as strong as injection molded buildings due to the many glue joints

Would not the use of wood in a plastic building require that ACC or similiar be used? I wood would think that it would be more convenient to use the same adhesive for the model and the braces.

I like to use styrene to brace styrene structures, mainly because a bond made between two pieces of this material using solvent-type cement is both strong and permanent. If you’re using a different material for bracing, the best choice for joining two dissimilar materials is contact cement - it’s more permanent than ca, although it can be messy to use.

While you can use strip styrene (or Legos) for bracing, I prefer using .060" sheet styrene. I buy it in 4’x8’ sheets for scratchbuilding large structures, but it’s also useful for adding floors and roofs to simple buildings, and adding floors and interior walls in multi-storey structures. For individual wall bracing, I cut it into strips of suitable widths.

Here’s a fairly large station, built from .060" sheet styrene…

…and its very simple bracing cut from the same material:

For this modified Walthers kit…

…I created partition walls to act as bracing. The roof is also made from the large sheet material.

For simple structures like these background flats, cut the sheet material into strips, stiffening the walls both horizontally and vertically:

This larger structure complex was made using DPM modu

I also use scraps of styrene, .040 sheet, .060 sheet, pieces of 3/8" angle, 1/4" square, 1/8 x 1/4" and other large sizes.

On this 38 in long bridge that had a roadway on top, I used a 1/4 bass wood for strenght,( top corners) , as the sides ant top are on part to be removed for track cleaning. On longer bridges I used metal strip structural rigidity, how ever all my bridges are built in sectons and can be removed in seconds and are designed to stand on there own compressiom, no glue

Hi!

I’ve built some kitbashes involving “double length” structures (i.e. loco enginehouse, warehouse, icing and oil platforms, signal bridges, etc.). I’ve found that in some cases - the more intricate ones - you use the size styrene that fits - both physically and cosmetically.

But the big structures - enginehouse and the like - require structural bracing that will do the job without messing up the interior of the structure (that one can see once the structure is planted). Like “real structual engineers”, I’ve found that “I” beams are excellent. There very nature resists bending in any direction, which of course is what we want.

Yes, you can use a second layer of flat styrene - which will do the job on smaller structures - but may not survive the test of time as eventually warp as well.

For what its worth…