Fellow modelers,

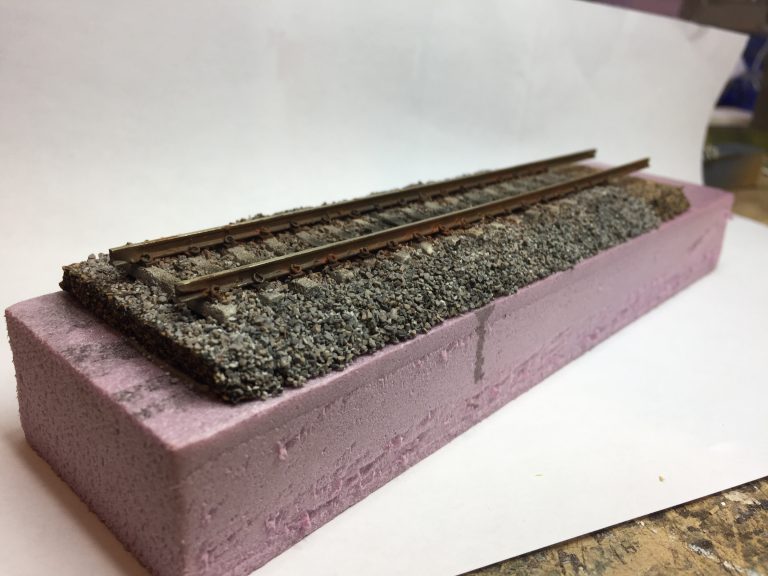

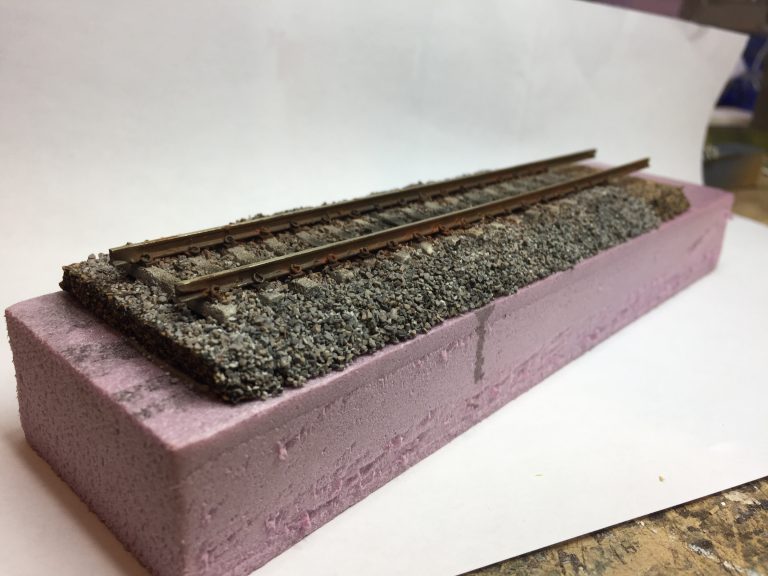

Since I found very little about the topic of handlaying concrete ties, I made a little mockup. Thus, I seek your opinion and experiences, if any, about it. I wrote a little article how I made it, you can read it here.

Thanks!

Fellow modelers,

Since I found very little about the topic of handlaying concrete ties, I made a little mockup. Thus, I seek your opinion and experiences, if any, about it. I wrote a little article how I made it, you can read it here.

Thanks!

I can see where the word “insanity” came up for the topic.

Very interesting.

Ed

I am a member of a small group of modellers who have built two layouts with handbuilt track - some switches and concrete tie plain track with pandrol clips.

I see that the above layout failed from flimsy framing (ah, alliteration! see: gorilla glue). Too bad, as it looked very nice.

That problem is something that is a constant in Free-mo. Well, for some modules, not all. Modules that are flimsy tend to get sidelined and/or retired and/or rebuilt.

Ed

Well, you did answer my (tongue in cheek) question about where to get 1:80 (close enough) scale Pandrol clips.

However, I’m not even tempted to hand-lay plain-Jane track. And my prototype kept the wood ties under specialwork. So, while I hand-lay the latter, I have sufficient Atlas concrete-tie flex on hand to finish the pertinent work - the final part of which is coloring the white plastic clips with black paint.

Chuck (Modeling Central Japan in September, 1964)

Trevor,

Thank you for the link, very nice work. ![]()

The track looks amazing! Great job!

I would suggest using something in addition to CA to secure the rails, though. I’ve had issues with CA letting go if the rails get bumped by a tool, or when soldering on feeders. Personally, I like soldering to PCB ties when handlaying track and turnouts - usually replacing every 5th or 6th tie with PCB.

Thanks!

I was thinking exactly the same; use a different adhesive for longer sections because I am afraid that CA is too brittle and would not be able to deal with expansion and contraction of rail due to temperature changes. The connection might just shear off. I would need to try something more flexible. I guess sneaking in a well-disguised PCB tie could do it.