Progress has been made!

The 6466WX box is complete. Or at least, complete enough for now. I’m feeling reasonably happy with how my reinforced hinges turned out. I had to layer some cardboard on one of the flaps which had a bad crease in it. I ended up applying the hinge over that.

Hopefully those flaps will all stay intact on the box for years to come.

And here the box is, along side the tender that will be calling it ‘home’- my lovely 6466WX.

Things are slowly progressing with the 6464-150 box, no new pictures there. Trying my best to eliminate warpage from the support I had to glue along one wall of the box.

The 0836-110 box is also making progress still. I cleaned up the original plastic window, and I’m quite happy to report it looks pretty good after a rub down with some windex. I haven’t quite succeeded in flattening it yet.

One of the end flaps finally let go while I was handling the box, and I decided to make it my next priority. In need of some reinforcement and fixing some de-lamination.

I cut out and glued a reinforcement piece, hopefully it works out well. It’s sitting under a brick right now to keep it flat.

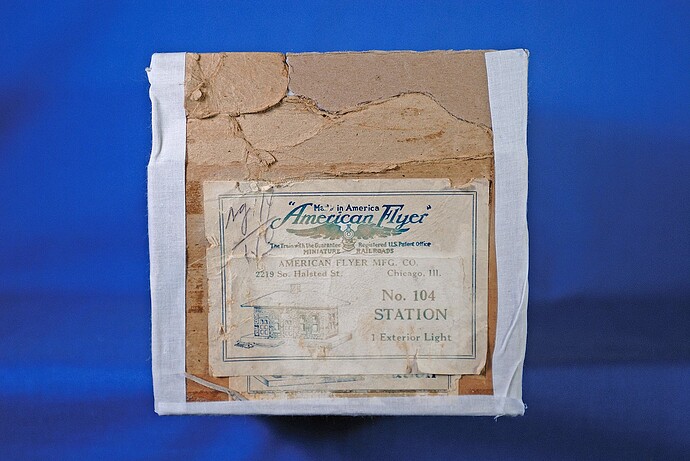

In a slight diversion, I was looking at one end of the box and I couldn’t resist fussing with the label trying to get a peek under it. And lo and behold, the old adhesive failed. And look at that!

I think this explains the purpose behind the paper labels pretty clearly. My theory here, is that the -111 suffix was an error, and the sticker label was applied to correct the mistake.

Now, why there were two labels stuck on this end is anybody’s guess, but they are identical.

Maybe two of them accidentally got stuck together while an employee was correcting boxes? Impossible to know without having been at the factory the day that the labels were applied.

Anyhow, that’s all for the moment. I still need an insert for this car. There is a seller on eBay who makes reproduction inserts for Lionel HO boxes, however I don’t think they currently offer the correct insert. This feels like as good an excuse as any to try and make my own! A project for after the box has been stabilized.

-El