Hello. Building 1st N Scale model RR since 1978, with son. He picked plan #43, which according to book has Sharp Curves and #4 Turnouts. We’re doing in 150% of N Scale plan dimensions (75% of HO dimensions on plan), so the radius are not so sharp - they are 13.5". We’re using the L-girder open-grid method, and I used 3/4" MDF 2" wide for the sub-roadbed. Question: The “101 Track Plan” book states #4 turnouts are required for all plans with “sharp curves”, and these do not change with a change in scale as the trunoput angle is constant. The only company I see that makes #4 is PECO, and at 20 turnouts * $18.00/each that gets expensive fast! Plus, the PECO aren’t even electric. Atlas makes a “standard” switch, sells for same electric as PECO does. What # is the Atlas “standard”? I tried to measure the angl and I got 13 degrees - not the 14.5 degrees +/- of a No. $ turnout. Can I use Atlas “standard” anyway, and how? Or, if we use PECO, is there a manual switching system that is easy, works, and doesn’t cost much? PECO + PECO ELectric throws = too exensive!! I had all electric turnouts in the 70’s…

Since you seem committed to this plan, I’ll just briefly mention that the ideas in 101 Track Plans are more than 50 years old and there are often better alternatives in the equivalent space. The track plans are often drawn with the expectation of handlaid-to-fit turnouts. But since you are using more space, you can probably work in commercial turnouts.

And since you are increasing the radius beyond the original drawing, you’ll probably want to make the turnouts a larger number too – otherwise you’ll be effectively limited by the turnouts.

In N scale, there is not exactly a PECO “#4” in the traditional sense. PECO N scale turnouts are offered in Medium and Large sizes in Code 80, and Small, Medium, and Large sizes in Code 55. In Code 80, the Medium is indeed a #4 frog, the Large is about a #7. But all PECO N scale turnouts have a curved diverging leg, which makes them different than a “standard” numbered turnout.

In PECO Code 55, all three sizes of turnouts use the same frog, about a #6. The difference in Small, Medium, or Large is related to the radius of the diverging leg (12", 18", and 36" respectively).

You will be relaying out the plan anyway, so you can probably use slightly larger frog numbers or other turnouts from atlas or elsewhere. If you use off-the-shelf turnouts, they won’t match the drawing in 101 Track Plans exactly in any case.

For PECO, the least expensive manual switching system is built-in at no extra charge. They have an over-center spring that holds the points in place and you can simply flick them with your finger.

Best of luck.

Peco turnouts indeed aren’t the cheapest option at first glance but on the long run are worthed every penny.As said,they have their own locking spring so that you can get away with switch motors or other systems(hand throws,etc) but,the most important is their reliability.They’re my personal choice.

You could go with Atlas but then some locking/switching device IS required.I know that Micro-Engineering makes very nice trackage but they aren’t cheap either.Then you have the Atlas “Snap-Switches” that will offer a powered turnout for about the same price if not lower,but if ugly hardware and somewhat reliable operation is your goal,then have it this way…

You might want to consider downloading the Right Track System from the Atlas Website, and seeing how the layout might translate to Atlas c55. They make #5, #7 and #10 turnouts, and are promising delivery of a curved turnout shortly.

This will give you a much better looking layout than you can achieve with Peco track, which is pretty clunky looking due to the oversize ties (even on their c55). The price and availability of Atlas track is also a lot better. Yes, you do need some sort of switch actuator, but this can be as simple as an off-the rack Caboose Industries throw, or a cheap micro switch you can get from electronics supplier.

You definitely want to look at the source through the lens of 50 years of improvements, both in terms of layout design as well as product availability.

I hope this is useful.

Lee

Since you are going to need to redraw the plan anyway, draw it using the turnouts you’d prefer to use. There plan is going to take tweaking, in any case.

Thanks. What is the best remote switching system for PECO? i.e. - is there a push-pull rod-in-tube system out there or are these homemade?

Also, have been reading “Easy Model RR Wiring”. Looks like power routing turnouts like PECO offer better control, esp in yard. If I use Atlas - code 55 or 80 - is there live wiring a huge disadvantage or can they be made power-routing by isolating the Frog ends and routing power through the switch machiine. I assume then if this can be done that means manual Atlas switches are out of the running as there is no dpdt electric switch to throw…

THanks. So the Atlas code 55 do not lock in place? I know the PECO’s do - I handled an HO PECO and assume the N work the same… As far as Atlas snap tunouts, I assume you mean the code 80 - the old standby’s that I used in the 1970’s? THe small ones will work on that plan with some tweaking. I was wondering how reliable they are today - seems like I had problems in the 70’s…

THanks - looks like I need to get up to speed on switch actuator if I use Atlas Code 55… So, any specific suggestions other than Caboose Industries? Also, isn’t Atlas code 55 all-live turnout wiring a operatioanl handicap? “Easy Model RR Wiring” book points out advantages of power routing turnouts such as PECO. It also points out potentail probelams w power routing and suggests “wir around” schems to insure reliability, which looks like more work…

I use a small micro slide switch. This gives you a solid switch throw, plus the contacts you need to wire the frog. I drill a small hold through the plastic slider, and insert a bent length of steel wire. This gives it plenty of spring.

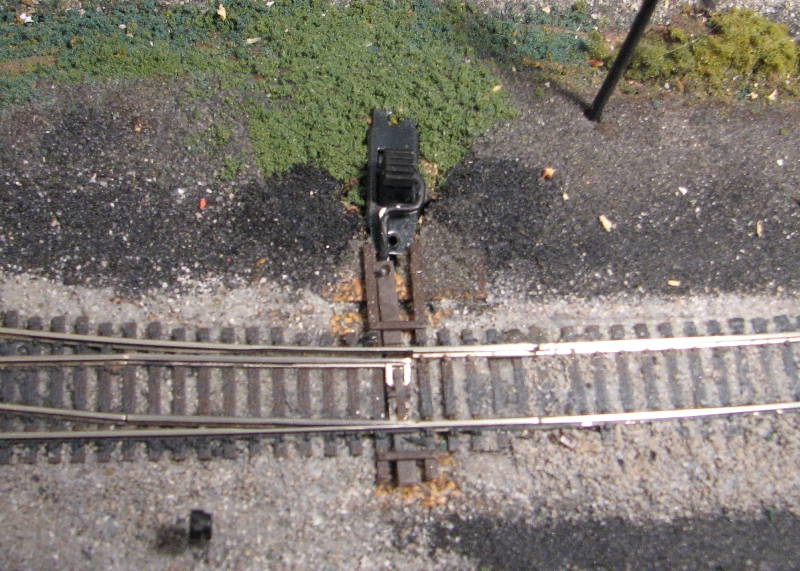

Here’s an overhead look…

I have a foam scenery base, so I just wire the switch, cut a slot in the foam, and wedge it in. Then I install the wire to take care of any fine tuning. At that point, I surround it with some scenery material and dribble some diluted white glue around, being careful not to flood the switch. Once it dries it holds up just fine under regular use.

These cost less than $1.00, and can often be found on ebay in bunches.

Lee

At the local club,they’ve installed quite a few Electrofrog code 80 without bothering with power routing and never really had any problems for years.As long as your trackwork is clean so that the moving rail makes good contact (Peco’s spring takes care of this) you would likely get away with it too.Strangely however,they installed power routed ones lately and these are the ones they’re having problems with…

You could install Insulfrog and never really have any issue other than an occasional very short loco or a loco that has faulty pick-up contacts.But Insulfrog aren’t available in code 55.

The trouble with Peco N scale track is the ties are set up for European N which I believe is 1:150. It just looks too chunky when compared to the Atlas c55 or Micro Engineering.

L

When painted and weathered, I just don’t notice the PECO appearance that much. But I admit I could be in the minority. (I also think the PECO On30 track looks fine and some purists scoff at that, too.)

Problem is, Atlas C55 N has no #4, tough for those of us who model tight terminal trackage. That PECO Small works like a charm – and looks OK to me when I bury it in the ground (as my prototype’s ties were sunk in the ground for the most part).

Hi

In Europe we believe on sunday; and N scale is 1:160 too. Even track width is the same.

Paul

You’re right… I think it’s those wacky Englishmen and the Japanese that use the different scale, but the same gauge… Either way, the new Atlas C-55 track looks a whole lot better than Peco, in my estimation.

Atlas c-55

The Other Leading Brand… (c80, Peco turnouts, Atlas flex track)

It’s like someone went around with a tire pump and inflated all the ties.

Lee

Not really a fair fight, Lee. [:)]

The photo you showed of the C55 is nicely ballasted, with the ends of the ties hidden by ballast.

The C80 photo has the ends of the ties hanging out with no ballast in part of the picture and with the track and ties unweathered.

Yes, the Atlas C55 looks better. But the PECO C55 doesn’t look too bad painted, weathered, and with ballast.

Since you are relaxing the dimensions larger turnouts should be able to be worked into the plan. You might have to pinch a radius down to 13" in certain areas to make that work.

I had just discovered the Peco turnouts in 1984 when I finished my N-scale layout. I wish I had discovered them sooner they snap so nice. “electric” can be easily added.

But having said that, see above, I believe the Atlas standard switch can be worked into the plan since you are relaxing the dimensions.

YES

They have built in springs and do not need a switching system for manual. In fact to use them with remote controls it is often better to remove that spring.

Peco high price - but back in 1984 the difference in quality was well worth it. I don’t know if Atlas has improved their product since then, I know the whole code 55 line didn’t exist back then.

Since most of your questions seem to be getting addressed by others, I’ll confine my post to just a few things.

First, Atlas code 55 offers a #5 turnout. Thats not too far off from what you were wanting, and Atlas code 55 looks pretty nice.

As for turnout control…

Slide switches were mentioned, and so were Caboose Industries throws. Those caboose throws can look less oversize with a few tricks: http://www.conrail1285.com/news.asp?storyid=31 . Also, a simple and inexpensive trick caan be found here: http://www.telusplanet.net/public/crowley/ground_throws.htm .

If you are looking for rod and tube type manual controls, go to “Humpyard Purveyance” for some nice looking manual controls. The pictures pretty well explain how it is done. If nothing else, it could give you an idea on how to rig up something similar using your own ingenuity.

EDIT. I am also in N Scale and use Peco track & turnouts. The track looks OK to my eyes once it is weathered and ballasted and the switches operate flawlessly as long as you do not get glue in the mechanism. Go ahead, ask me how I know. DOH!!!

Good luck.

Blue Flamer.

Hi,

I have used Peco code 55 in Nscale from it’s beginning for my layout.

They run flawlessly and whithout any maintenance in the time.

Yes, the ties spacing are a little bit out of American looking track, but well weathered they look fine.

Use only the Electrofrog series because it avoid some locos to stall in a ladder or on simple turnouts.

Because I use Switchmaster motor and some Tortoise, I cut the two eyes/pins away from the trowbar, I drill a hole in the middle of it, just where you see a very small rectangular tab preformed in the plastic. It’s for the motor actuating wire.

I also cut away the “plastic plates” where the Peco motor could be mounted. Thats mean you need to glue or fasten the turnouts before laying adjoining track, because the structure of the turnout is less strong; but anyway you have an improved looking turnout in Nscale.

I am very happy whith these turnouts, but for the expand of my layout I will use Fastrack turnouts www.handlaidtrack.com, they offer jigs to build semihandled turnouts from a n° 4 to a great n°12.

They also offer jig to make crossing, double slip and flex track whith code 55 and all the tools you need to build them.

This line of products is quite expensive but if you need a lot of turnouts ( more than 25) you can produce your own turnouts whith the best running qualities and electrical continuity I ever seen in Nscale; far more they are close to the scale when using ME flextrack togheter. They are DCC friendly.

My expand will need a lot of flawlessy turnouts whith n°6 for branchline or industry track and n°8 for all crossover or siding; I will also use some n°8 curved ones.

I have alr

Thanks for your and everyone else’s responses. These have been lots of help! But, but I’m still confused on two issues:

-

I always had the impression that “real” or “professional” model railroads always used some sort of remote swicth control. However, the manual “finger on the switch” method seems to be used by many model railroaders… With the “Finger method”, it seems like train would have to be stopped often while the points are being thrown by the finger, and this appears clumsy, whereas w remote swicthing this could be done seemslessly, faster, and allow better RR operation… So, remote vs. manual - not a significant difference?? If remote is much better operatioanlly, then cost quickly becomes an issues, esp w PECO switches. Atlas Code55 would require a smiliar investment in switch machines/levers, etc. as PECO. Atlas Code 80 electrics (I need 20 turnouts!!) seems like its works with layout #43 and provides inexpensive remote swicthing.

-

Insulated Frog’s (i.e. Atlas) vs. Electrofrogs (i.e. Peco). “Easy Model RR Wiring” mentions significant control advantages using power routing (electrofrogs) turnouts vs. All-live turnouts (insulated frogs). I totally get how to wire electrofrog turnouts and see the advantages, i.e. loco’s can be on the track not lined up by points and they don’t move; only the loco on the “active” track moves, and the “active” track is control by lining up the points. However, I’m not sure how using “all live” turnouts effects or diminishes opertaioning capability. Seems like “all-live” switchyards would be a problem w two loco’s using Atlas. But maybe the difference between the two is really insignificant, and therefore other factors like cost, scale appearance, reliability are more important. As PECO appears to be the only electrofrog turnouts choice, its either Peco or "all-li