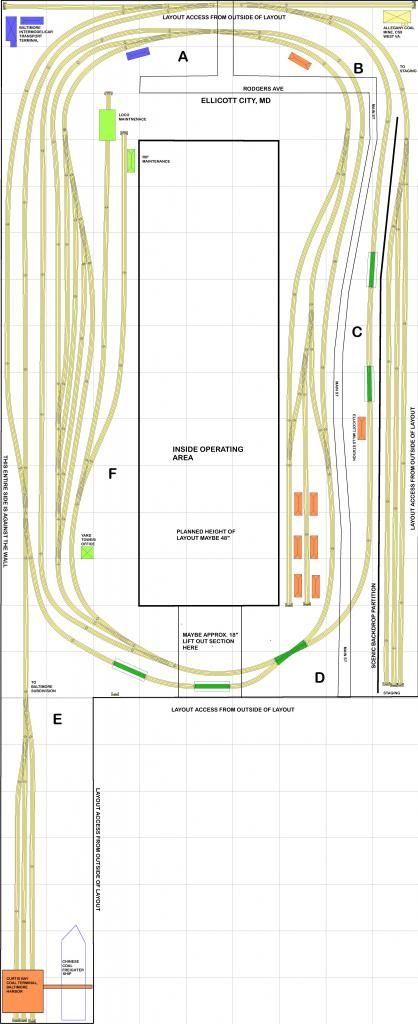

Hello again. Here’s my latest update to the RRN layout. As you’ll see, it has changed quite a bit, and I’ve tried to include most of your suggestions. I’ve been reading and researching quite a lot and am working to make this first layout operation friendly. However, I still have lots of questions. The main one is, how can I incorporate a way to turn the trains around and have them run in the reverse direction? This is not a large layout, so I realize that this may be a challenge. From my research, I learned that my CSX Old Mainline carries a lot of WV coal, loads of car carrier box cars and some miscellaneous freight. I added staging, switching and tried to follow the concepts explained in Armstrong’s Realistic Layouts book and the MRR magazine books. But I’certain that I’ve overlooked or misinterpreted some things. I’ve labeled sections of the layout with alphabets to make it easy for you to reference sections that have problems. So this is it. Please feel free to express your comments. I have thick skin, and intend to keep chipping away at the design until it’s the best it can be for the space. BTW the layout era is approx 2000 to present. Thanks for your time and help, Rich[:)]

Do you want to add reversing loops to your plan? Modern equipment (2000+) might require long modern cars and appropriate radii and turnout numbers. reversing loops with those large radii could easily be impossible, unless you are willing to accept a couple of duckunders. Since you own John Armstrong’s Track Planning For Realistic Operation you could opt for a smaller version (length wise) of his StCSW plan (3’d edition page 129). When sticking to the twice around scheme, no easy change of direction no staging either, John Armstong’s plan called Tailored For The Wayfreight (page 139) could be inspirational.

Your drawing is lacking lots of information, size of your plan, grades (none), radii, turnout sizes, trainlength etc.

BTW if your are to lazy to draw out your room, despite being asked by e.g. Cuyama (Byron Henderson) and me why do you expect me ( or others) to be willing to find alternatives?

Smile

Paul

Just a little remark - some of your track is way too close to the edge of the layout. You should allow for at least 3" from the track center.

"BTW if your are to (too?) lazy to draw out your room, despite being asked by e.g. Cuyama (Byron Henderson) and me why do you expect me ( or others) to be willing to find alternatives?

Smile

Paul"

WOW!

'Good thing you’ve got thick skin,Rich!

Smile

Mike

Dimensions of the layout and scale of your trains would be helpful, as some of us are not too good at remembering earlier posts which may contain the information.

As for turning your locos. The only place I see that you could do it is in the lower left corner where your staging (?) is attached. You could put a wye there.

The other option I see is to run double headers, common these days, with one loco headed in each direction so that you would not have to turn them at all to reverse direction.

Yes, keep your track away from the edge. I have some, that of necessity is close to the edge. I have installed a safety fence along the edges to keep the trains from diving to the rather hard floor.

Have fun,

Richard

hi gentlemen,

these were his words in his other thread:

" As far as a drawing of the room, I just didn’t wanna take the time to sketch a drawing in Rail Modeller, upload it to Photobucket, then post it on the site. "

wow

Smile

Paul

Wow indeed. Sounds like the guy doesn’t need help that badly. One would think that providing the greatest amount of information would be the quickest way to helpful replies…

Hmmm…I don’t recall the previous thread’s plan having an appendage at the bottom of the plan. That addition actually changes a lot of things.

If it is to be an industry that is switched when operating, then you’ll have to duck in and out of the pit to either switch the industry or correct derailments.

The appendage would be better suited for staging, where you build the trains before and op session, then duck into the pit; never having to leave it.

Then you can remove the staging on the right and spread things out to address the clearance issues Sir Maddog raised.

Also, the track in the NW corner is unreachable from the pit.

You’ll find that suggestions will change from plan to plan if you keep changing the space available.

Layout appears to be 16x9, with a wall on the left hand side. Wye at point B would work, sure seems like a bunch of track for the space.

Opp’s, I meant point E

Man, you guys are tough![:)] So lemme see if I can deflect some of this flack and maybe receive a teeny bit more help. LOL! First off, the layout is drawn on a 1ft per square grid. I guess I should’ve mention that earlier. That means that the main box of the layout is 9X15ft and I’ve added a 2X7ft extension along the lower left wall. Yes, I’m sure you can see that now. The room that the layout will be built in is a 13x32ft box, and I plan to place the layout along the left wall. I cannot expand the layout into the remaining space or mount tracks to the wall due to furniture etc. This is what I have to work with, room drawing or not. I had mentioned this to my friend Paul in the earlier post. I may be able to stuff a wye or reversing loop into that lower left corner, but I don’t know how much radius will be required to maintain 24" minimum, and I can’t expand the layout to 9x22ft. So that’s it.

All turnouts are #6’s and the track used is Atlas flex track. I have good access to the layout outside the pit on all sides except the left side against the wall. For that I’ll have to reach from inside the pit which will be a stretch to the very outside. There are no grades planned at this time. Yes, I will move the tracks away from the edge of the layout. I have not confirmed the radii used thus far. Am not really sure how to yet, and have tried to keep them as large as possible. Will certainly verify before I start the build. I plan on purchasing a radii gauge from the HS. Am reviewing Armstrong’s “reversing loops” and pages 129 and 139, Appendices A & B for other ideas. For train length, I’ve learned that this affects the siding lengths and minimum curve radii used. So I guessed 10-15 cars, and if necessary, I could run the shorter cars from an earlier era. That’s TBD for now. I have already purchased a Kato CSX

I made a mistake, guys. I had been looking in the MRR 2013 planning mag at the article “10 Ways to Wye” and all of the examples given used a wye with a circle of track. So I thought that if you used the wye turnout, that it had to include the circle of track. That’s why I asked how to figure the radius of the circle of track needed. So I don’t need to do that circle of track since it requires a lot of space that I don’t have. Lord knows I’m glad I caught it before you responded and took me to the woodshed again! LOL So I’ve seen that I can insert a basic wye into the lower mainline near section E and extend track down near the ship for turning the loco with a few cars. I know this is not prototypical, but it will get my locos with a few cars reversed with out any additional space required and provide better operational flexibility.

Rich

Thanks, Mr. Broadway Lion!

I would be cautious about designing a plan where you have to use the appendage for normal operations. Ducking in and out of the pit will get old after the first operating session.

Rich,

you do have the book by John Armstrong, which is great for references. However with almost every line you have written you are creating new misunderstandings.

IMHO serious help needs a serious attitude from the one asking for help in the first place. Our host is not Rail Modeler, nor is John Armstrong’s book titled Realistic Layouts. The difference between “a wye” and a “wye-turnout” might have escaped you, however in Model Railroad Planning 2013 all ten drawings were not about a wye-turnouts.

In your first post of this thread, you asked for an easy way to change the direction of a train. That’s why I asked if you wanted to have reversing loops. Another member talked about a wye, the question you meant was only about easily turning the direction of a train in the small terminal on the harbour-extension. This exactly was an issue where it will cost easily a few hours to think up alternatives and find examples or make my own drawings to illustrate my lines of thinking. Finding out later I was off the track completely due to unclear information.

To take you to the shed once more, you could mention which concept by John Armstrong you followed. Most important, though often neglected, is chapter 6 about standards. If I did understand you well you are “planning” to use modern freightcars. You were talking about car-carrier-boxes; modern auto-racks are 90 ft long, about 1 ft in HO. They require radii of about 30" and the use of #6 turnouts, even #8’s in case of a crossover. The original RRN was build for smaller cars from the 50’s, not longer then 40 or 50 ft. Number 4-turnouts and a 18" radius were an appropriate choice. Lance Mindheim design standards are #6 turnouts, a 24" radius and 4" away from the edge; his railroads depict the 70’s when cars were between 60 and 70 ft at most.

Looking at your plan you obviously would like to run long trains, even when this means you have

Just so you know LION, your Server isn’t serving up the pictures when you post them.

Dennis

Doughless, I agree. Each week I learn more, and am now understanding that the operating trend is to follow your trains around the track during ops. So I have to work this issue out.

At present I’m planning to use radio DCC radio throttles for train control. I am also considering the possibility of using DDC controlled switches. Can someone comment on the present day reliability of this approach? Are the problem prone? And I would think that it will probably be a significant expense for the number of switches I currently have in the layout. Please comment. Thanks, Rich

Hi Paul, thanks for your worthwhile, detailed response. It is really appreciated, and I certainly apologize for the confusion I have occasionally created. But I am serious, and you’ve got to give me a little patience. I only decided to try model railroading about 6 weeks ago. At that time, I new nothing much about it; nothing about eras, trains or prototypical operations. So I’ve bought a bunch of books and started to try to get up to speed, and I still don’t know what I don’t know and don’t understand some concepts, but I’ll get there. So hopefully you can accept that I will occasionally misspeak and get used to it if you’re gonna continue to respond.

So in my statement about wye, wye turnout, etc., I misspoke. I looked at my layout and saw that the trains would aways be going same direction forever. So I started trying to figure how they could be reversed. I read Armstrong’s chapter and saw that the info on reversing tracks, fig 8-1 probably wouldn’t work for my layout. Then I remembered the “ten ways to wye” article in MR planning 2013 and figured that I didn’t have the space for the loops associated with each example. Then I remembered Armstrong’s figure 4-1 which showed a simple wye. This was my solution to turning my trains, and I put it in the layout at the bottom.

I chose the RRN layout after reviewing just about every track plan in the MRR database. I really wanted a walk-in plan, but they were all too big and complicated to me at the time. I didn’t understand what a lot of the spaghetti track did. I’ve since learned a little more. So you’ll remember the RRN started as a 9x11 size, and I’ve expanded it to 9x15 the the 7ft extension at the bottom. I’ve also shifted it down the room box away from the window 13 ft. That’s how I was able to add the 7ft extension agianst the wall. So the wife has her furniture

Problem is how hard and how many times I looked I do not see a wye at the bottom of your plan. Hence I used it as an alternative in my second plan.

Radius is the most important design issue. To small and the cars you would like to have will not operate well (derailments) especially when long cuts of cars are shoved. To large and you will find out you can’t avoid duckunders, if it will fit at all, or you end up with to limited length for stations. Height and reach-in distance are the next issues to be concerned. The larger your radius the sleaker (longer) turnouts you’ll need as well.

Keep in mind a lot of plans are dating from or modeling the 50"s when freightcars and engines were half as long as they can be to day; between 30 and 50 in the past while todays autoracks are 90 ft long

Multiply the prototype length with 12 (from feet to inches) then divide by 87 (the scale). Dividing the prototype length by 7 might give you a pretty good idea of the over-the-coupler-length of our models without using a calculator.

BTW, yeah, it can take quite some time to fully understand everything he explains. Try to keep thinking in trainmovements all the time.

Smile

Paul