I fear I must be a simple soul, but as most of the track I’ve laid, new and used Peco, GT Italy, and Atlas, is laid directly on to MDF or plywood, I don’t see the problem with drilling each track nail hole.

For laying straight track, I use a string line, Bruntons method, and the Mk 1 eyeball.

C’mon Rich, yer stalling![;)]

Cheers, the Bear.[:)]

Drilling every hole is just too much work. I’ve found that setting the track in cork and pushing one of the Ribbonrail stright pieces along it makes it nearly perfectly straight, sighting along it there are few if any deviations, nothing enough to cause a problem. If there is, a gentle nudge fixes it.

I once built an N scale layout on sheet homasote. Sure was easy to push the track nails in, by hand, without shoving the track around. It was also equally easy to remove it - I reused the track AND the nails, the pulled out that easily. I still don’t understand where homasote got a reputation for spike HOLDING power - easy to push them in, absolutely. But they aren’t held in worth anything. Add ballast and glue it down, and your track will stay, but just nails? Not so much.

Peco is a decent compromise - it still forms nice curves like Atlas, but only springs back part way - at least the Code 83. I don’t know about the Code 100 or Code 75. Definitely way easier to work with than ME.

–Randy

Randy,

Your homasote experience is very interesting, never heard anyone else have that opinion/experience.

I have build, or been involved in building about a dozen layouts with homasote roadbed, and homasote sheet for yard areas over the last 40 years, some with commercial roadbed like Homabed or Cascade, others made their own

Long before track glued with caulk, I learned from the masters at the Severna Park Club how to hand lay track/build turnouts with spikes into homasote roadbed and Campbell profile ties. The spikes are placed next to the ties, not thru them.

I built my second layout that way with no issues. The Severna Park layout is now pushing 60 years old and still running fine with mi

I have always used minimal nails, and ballasted the track as soon as possible.

.

Glue and ballast hold track in place better than spikes ever will.

.

-Kevin

.

What did you use previously?

Have you used Fast Tracks SweepSticks?

Ribbon rail fits between the rails, like sweep sticks. Ribbon rail are made from metal.

Mike.

Sheldon, laying track that straight is just plain disgusting![swg][(-D][(-D]

Seriously, that is excellent track work.

Dave

Long ago, I offered $10,000, no questions asked, to the first person who could teach me to drive a golf ball 200 yards into the fairway on all 14 par 4 and par 5 holes in a single round. I still have that money in my account. [sigh]

So, I am extending that offer to the first person who can teach me to lay “laser straight” track on my 10 downtown passenger station tracks running 12 feet each into the train shed. [swg]

Rich

Oh No!!! Not the dreaded Fiji warbonds!![+o(]

Actually I have full confidence that you can and will achieve that goal, yourself!

Cheers, the Bear.[:)]

Bear, I have warned you before about revealing the source of the funds. This has all gone on too long. I have filed a Report Abuse on this matter! [8o|]

Rich

Thank you for the kind words.

To quote Paul Mallory, “excellent trackwork a must”…

The secret:

Proper materials, good methods, patience, practice, and careful design and layout.

Sheldon

I’ve found that laying arrow straight track isn’t at all difficult, at least the way I do it, and I wasn’t trained by any guru’s.

In case it was missed, and it might have been since there is a whole new topic on it, I obtain a nice long “true” piece of lumber to use as a straight edge and draw centerlines using it. If I have multple parallel tracks, I measure over my chosen distance (e.g. 2.0 inches) and make a mark about every 12-18 inches and then lay that long piece of lumber down and draw another straight centerline.

As long as I make sure that I nail the track down so the nail is on the center line, the track will be straight. And since I used Atlas track nails there is a bit of wiggle if I need to tweak it a bit as I sight down the rail to visually make sure the track is dead nuts straight. It works for me very well.

Agreed. We don’t need NASA precision for track to pass the eyeball test. I’ve successfully built three layouts and I’ve never even used a centerline for laying the track.

I understand Rich’s concern (this thread or the other) where a minicam might reveal unprecise straight track where you once swore it was. If I get to that point where that’s a concern, I’ll use more precisely engineered methods for getting track and roadbed laser straight.

As far as a centerline, its never been that difficult to just eyeball the space between the tie ends and roadbed edge, so I’ve never bothered to use the seem in the middle as a guide.

Besides, I always thought a center line was drawn mainly for laying curves, where you have to separate the roadbed into halves for it to curve sharply, in which case you would want something as a reference point to keep the curve consistent. But for straights, the eyeball detects wiggle in the track just fine for me.

Yeah, it is my “laser straight track” obsession that haunts me every since buying than darn mini cam a few years back.

It is those “precisely engineered methods” that I am searching for.

I also planning to purchase a 98" straight edge. I have read the mfg. brochure and it is designed to accommodate 4x8 plywood sheets. It actually comes in two 49" sections with a metal joiner. My plan is to use it as two 49" pieces to “trap” a 36" flex track sections. I hope to hold down the straight edges with push pins.

http://www.johnsonlevel.com/P/133/HeavyDutyCuttingGuide

Rich

Rich, you saw my photos? That was done with a 36" aluminum yard stick and chalk lines…

Sheldon

If that’s the case, have you considered one of these??

http://www.johnsonlevel.com/P/1907/LaserMouse

Cheers, the Bear.[:)]

Where were your photos posted?

Earlier in this same thread…

Sheldon

I’ve used Ribbonrail 10" straight and 5" straight sections and they work fine. Same with a metal yard stick as well as a 48" level. Just take your time. I use HO cork on 1/2" plywood. Atlas track nails, a small hammer and I have no issues. In my yard areas, I drill holes in the flex track (1/8" cork), track nails and the small hammer.

As I said earlier, take your time.

Good luck!

Neal

I like to think I can be just as nit-picky as anyone when it comes to trackage . . .

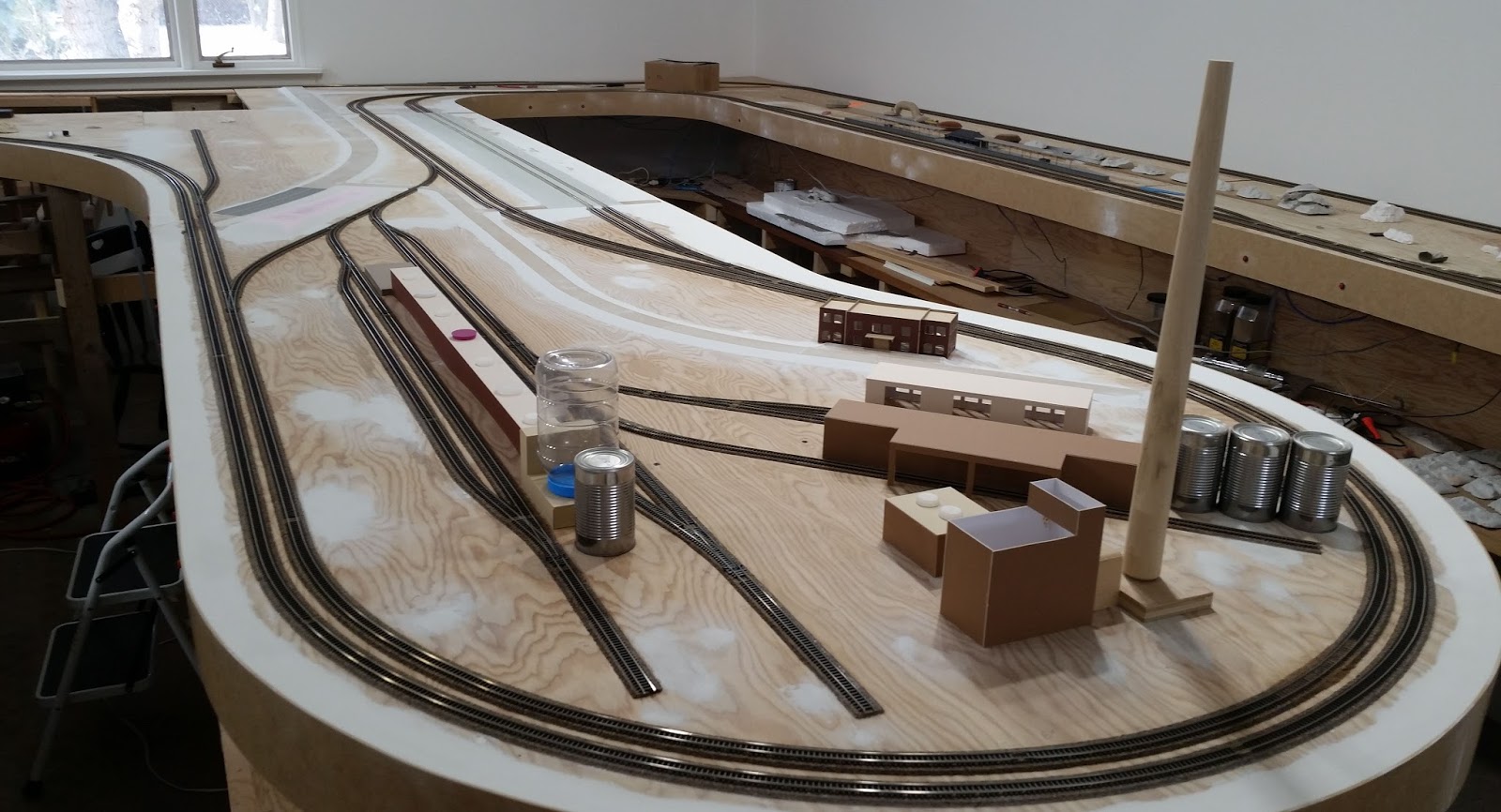

When I designed my layout, a specific criteria was for long continuous mainline runs with areas of straight track to allow trains to stretch their legs. After all, that is what prototype railroads look like. But in doing so I knew that I would have to actually build long continuous mainline runs with straight track: