if the (white) LEDS have a voltage drop of 3.3V, three of them will drop 9.9V. With a 12V supply, there will 2.1V across the resistor, a 1k resistor results in 2.1 ma ((12 - 9.9) / 1k)

I was an architect who trained on the drafting board, and I was the king of the board in our area. I was told I did the most beautiful drawings in town.Then AutoCAD came along and basically ran me out of the profession. I just could not gather up the mindset needed to understand it and even though I learned enough to use it in the workplace, I was never really fast enough or good enough, and whenever the economy would take a dip like it always does in construction I would lose my job. AutoCAD was my employment ruination until I finally got a great public sector job reviewing other people’s drawings for code compliance, which allowed me to retire. Later than I wanted, but retire.

Getting back to the topic of cardboard structures, as a young modeler in the early 1960s I had no access to a hobby shop and it wouldn’t mattered because I didn’t have any money anyway. But I had a lot of cardboard inserts for shirts cleaned at the laundry. And I built many a cardboard structure for my layout. The problem was, in a humid climate like ours, surfaces of any size would warp. Of course, being the bright bulb that I was, I never did figure out that you could put some kind of reinforcing like popsicle sticks behind it to keep it straight. I wish I had pictures of those buildings. None of them survived. I’m sure they were clumsy and inept, but they fueled my Model Railroad dreams well for the ability I had and the times they were in. I think I can safely say that I had more fun with them than the kits I build today.

Can you show a diagram? Curious how to run LEDs on DCC…

just wire an LED and resistor across the rails

A few days ago i made a foamboard (same principle) mock up of a great idea for my layout.

Nope. Not such a good idea. Glad i didn’t dive in to the real model.

Dan

Value proven. I wish I’d thought about this several years ago when I bought several large plastic kits for industries and customers on my layout. They are all too big, I realized after I bought them, but before I built them. They’ve been in storage all this time for some glorious day with unlimited space in the future.

Of course gregc! Ohm’s Law v = ir or v1-v2 = (i1-i2)(r1-r2) … (I think). You is bringing back memories of Mr Ohm.

It’s all a question of how detailed you want your model to be versus how many of those details are printed on rather than made as fully dimensioned individual parts. A few examples of what can be done with paper, or more accurately 65lb cardstock.

This is Disneyland’s Main Street Station, a kit you can download, print and build from Paper Models: Page 1

And, well, you can see how you can take it from there ![]()

Even toys like this Standard Gauge Hellgate Bridge can be reproduced inexpensively with cardstock, poster board, foam core board and bits of brass.

I had a Thailand layout in my bedroom once upon a time with skyscrapers created from kits downloaded from Scalescenes.com.

Most recently I built this depot by hand measuring and drawing every piece. It’s not perfect but I’m running on three rails so ![]()

Is that different from the Fome-Cor that was a staple of architectural modelmaking in the late '70s? I had good results with it, using a mat cutter for the corners and to relieve apparent thickness at window openings. Then you can use cardstock (for relief) and printed paper overlays for surface finish. I used hot glue to reinforce the inside corners after assembly and had good results.

Yup. Foam core. Thats what i meant. Dan

corners are a challenge for me with cardboard.

i’ve wondered how thicker cardboard covered foam panels would be joined along edges. wouldn’t it be best to cut the edges at a 45°?

bending is preferaable but i’ve also tried lightly scoring one side to create a sharp corner which is a bit unsatisfying. I’ve yet to try glueing panels together on 1/8 balsa

i’ve built larger structures out of corrugated cardboard because it comes in large pieces. i’m satisfied with using a screen window tool to create a bend.

Yes; as I said, the tool to use is a mat cutter – a tool used in picture framing to cut the beveled openings in framing mats. These usually use a knife adjusted at a particular angle that slides across a straightedge or other guide. Note that the blade depth is adjustable, so you can score panels for bending without breaking the face on one side of Fome-Cor.

The ones I used had the rails built in, for ‘production work’ involving many cuts an hour. These are expensive unless bought used, but become very valuable when many precise cuts are needed.

Let me back up. I already know that; I was responding to the statement:

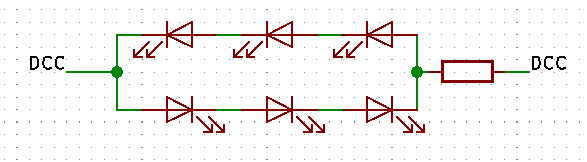

2 strings of LEDs can be wired in paralell with opposite polarity if the voltage is AC (i.e. DCC). 2 strings of 3 LEDs in parallel will draw just ~10ma

That’s what I’m curious about. Strings in series? Resistor or not?

He’s talking about one string ‘each way’, each effectively powered by half-wave DC. Think of it as a diode rectifier that also happens to make light from the diodes when they conduct.

The strings could share a resistor, as that is not a directional device, and only one string will be conducting at a given time. The resistor would be sized to keep voltage across the diodes within spec.

Illustration board is excellent also. Currently I’ve been using “boards” that are for “Silver Age” size comic book preservation. I bought a pack of 100 but I didn’t have nearly that many comics to store. So, I started using them to make stuff.

This is the inner tank of the water tower I’m building. The exterior will be actual wood glued over this liner. As an experiment I used some scraps to make a fairly convincing I beam.