I’m showing my age here, but I learned at an early age the use of waxed cabling twine in making up wiring cables on the layout. I haven’t heard of any still being made, which would be a real pity - it was much neater and more versatile than these ugly zip-ties we have now. Any of you other old-timers know of a source for this stuff?

Not sure what exactly you are talking about Gary but I know of a couple of products that fit that discription. Waxed sail makers twine is waxed and made of heavy duty 1/16" (approx.) nylon. Comes in spools of several hundred feet and can be readily gotten at any marine Chandler. I have seen a nylon flat thread of similiar quality but can remember where at present.

I never thought of using the stuff for bundling but it sounds like I make have to try it as the wires do get unruly after awhile.

Fergie

PS I still get rave reviews regarding the decals

It is lacing cord. Do a search with the two words. I used it a lot when working for Kaman Aerospace building the SH-2 helicopter. Nylon ties made the job much easier when you had to do a cable repair/modification.

rich

The above post is correct. It is lacing. We really don’t do any laving anymore (and I don’t miss it). I am a Kansas City type myself.

I know exactly what you’re looking for, and it is still available from Mouser Electronics. It is called Lacing Cord and comes in a 500 yard spool, with tensile strengths of 30 or 50 pounds.

Stock Number(s) 602-LC132-BK (black) or 602-LC132-WH (white); LC134; LC136; LC140; LC143; or LC162.

Boy did that ever bring back memories! When I got into the business 40 years ago, some techs. were still using lacing cord, but it was a dying art even then. I was taught how to do it, but I could never get the hang of threading it so that you could cut the running cord without the transverse cords coming apart. It does make a very neat job of bundling wires, but those plastic ties are soooooooooo easy to use.

[#ditto] Did it all in my day too. Early on we laced all wire bundles in the U-boats. Learned to be quick with the Lacing. Haven’t done that for years. I can’t imagine doing that under a train table.[:D]

The aircraft industry still uses it in some areas to bundle wires . As I recall it was a flat waxed nylon ribbon of sorts, great for tying up just about anything. As a gen. aviation mech I use it occassionally too when I’m out of zip ties!

My father used fly fishing line for doing his.

Chuck

From a '60s era manual

Basic problem today - most kids are not in the Boy Scouts in the numbers we were - and since velcro was invented, most can’t even tie their own shoes!![:P]

The modern material that does the same thing is a plastic spiral wrap. You cut it to whatever length you want and just wrap it around the wires. You can get very small spiral wrap or very large spiral wrap and any size in between.

You should be able to find it a good electrical supply stores and even Lowes or Home Depot. The beauty of it is that you can build wiring harnesses very easy to help control that “mess” of wiring that is always lurking around. And if you want to get to a wire to troubleshoot, just un wrap a section and pull the wire out of the bundle. If you have to cut the spiral wrap, when you are done just rewrap it back together, no harm done. If you want to add a new wire for some item, just unwrap, add the wire and rewrap.

Worth it’s weight in gold.

Also if you are hooking a bundle of wires from inside your control box to the hinged lid, warp it tightly with spiral wrap and you have improved the stress problems on those wires tremendously.

Using it you only need to use cable ties to hold the wires done at critical points only.

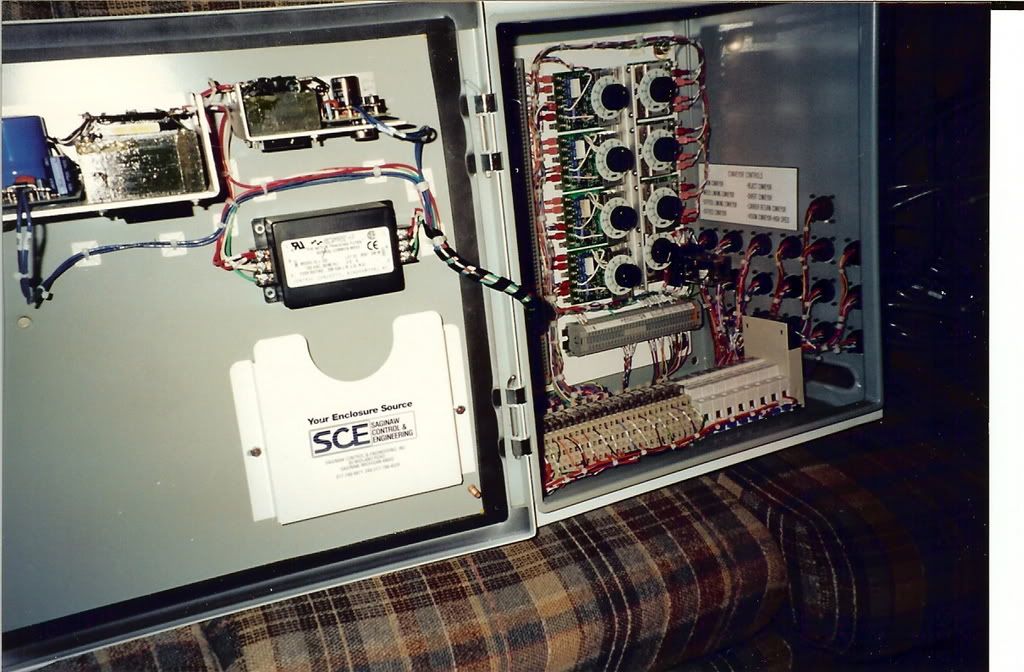

I don’t have my railroad wired yet as I’m still laying track so I can’t show you an example of how it looks for a model railroad, but I’m attaching a picture of a control panel I have done professionally.

You will see the spiral wrap on the wire bundle going to the hinged door.

Click on the picture to make it larger.

Hope this helps

Woodlandtoots