when i was at iron spike looking around i found a layout that had custom made pantograph wires out of peices of copper and working pantographs on the train engines, i was wondering if anyone else has expiremented around with this sorta thing. its neat the whole layout had them over every track and he sodered them togeather to keep the wire going

A lot of the Trolley Car and Street Car models have the option of powering the car through the trolley pole/pantograph or through the rail. I have seen model layouts, with the rigging and wiring of the trolley power lines. I have heard they take real patience to install and adjust to maintain reliable traction current.

There’s a fellow named Andy Rubbo who’s PRR catenary work I’ve always admired.

At one time I recall reading that he doesn’t run with ‘pans up’ due to fear of snagging wire and ripping everything apart. I seem to recall, too, that he was working on a ‘break-away’ pantograph for this reason.

I have several ‘motors’ and like to stage photos with them but I have no catenary either. Just some poles that I found at Shapeways. In this instance I fudged a little wire in with Photoshop:

Pennsy Electrics Through the Years by Edmund, on Flickr

Pennsy Electrics Through the Years by Edmund, on Flickr

Sometimes people will comment about the lack of overhead wire and how can I run electrics? Um, you have coal, water or diesel to run your engines?

I’m OK with it…

Cheers, Ed

Still, it would be so cool to see the pantograph touching those overhead wires. Need to find an effective way to do it.

Rich

Pan’s snagging the wire is not just a modelers problem, it happened in real life too.

I can recall that riding the Illinois Central commuter train. Also, the trolley cars in Chicago. And, if I recall correctly, there were some trolley buses in Chicago for awhile.

Rich

the one i saw in saint louis they had a short pantograph wire the driver would drive a bus under it raise the shoe touch the wire and go in the building when it was done charging they lowered the shoe and drove off

well what this modeler did was use copper plate peices and cut it out to look like the wire as much as he could and made sections and sodered them togeather from what i can remember of it next time im up there if they let me ill get a picture

Yeah, that would be a possible solution.

Rich

I would be very surprised if it isn’t still happening. Locomotives with two pans would often run with rear pan up so a snag would be less likely to damage the front pan. Pans are usually designed to break first.

how cool man u got it set

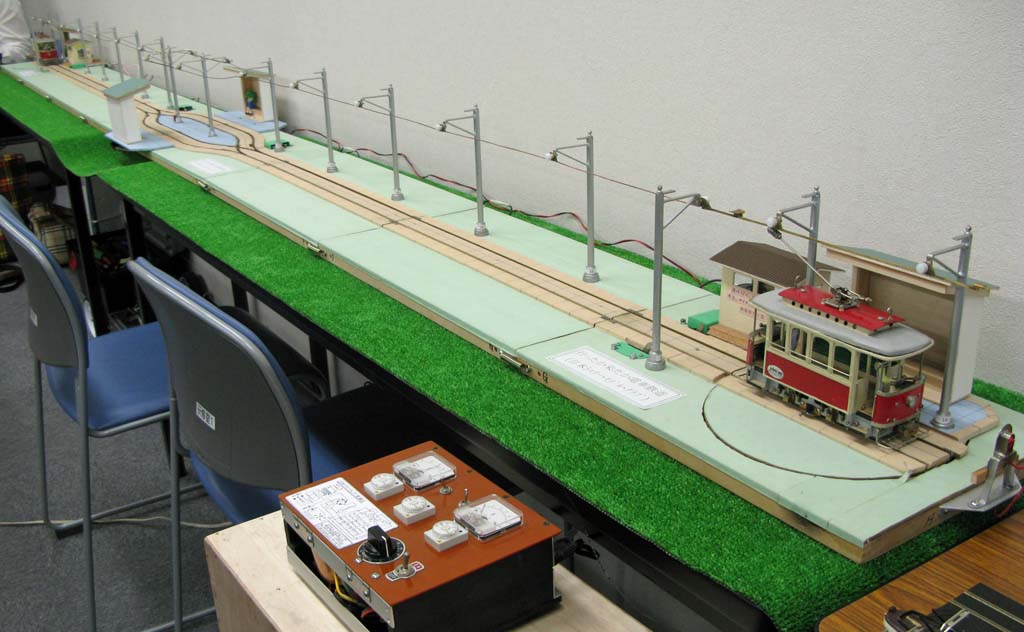

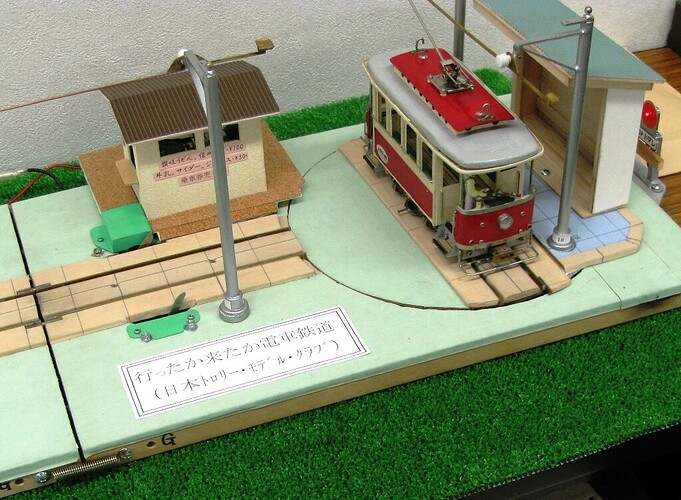

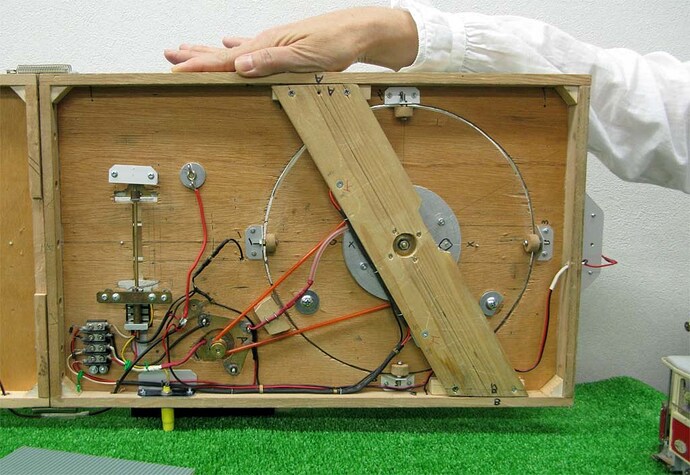

This is an O-gauge model railroad that Hideo Kuraishi showed at an event in the fall of 2009. Well, this kind of hobby is impressive too.

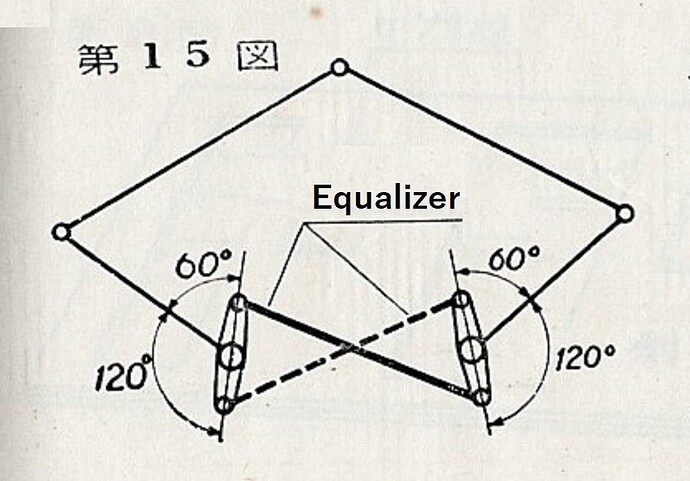

In Japan, this type of pantograph is called a rhombus. To actually make it work, a link mechanism called an equalizer is required. How to make this was serialized in the March and April 1956 issues of Railway Model Magazine (TMS), and following this example, I made several in HO and O scale. As a result, I discovered that an equalizer can function with just one rod instead of two, and that the angle does not need to be exact.

We have a lot of PRR modelers around here and a few of them have working catenary. I have not visited any of those layouts recently, but assume they are still around.

It is a lot of work and expense to build. I have know a few who just installed the towers with no wire, then limited the panographs with keepers to so they only go up to running height.

Originally, in 1965 the Severna Park Model Railroad Club was going to electrify the mainline, and even installed “working” catenary with no cosmetic value on some hidden trackage. But ultimately the project was abandoned.

Sheldon

A layout with working pantographs has to be a sight to see. Photos, yes. Videos, even better.

Rich

I don’t have any pictures or videos handy.

I have visited this VERY large PRR layout, he has/had the catenary structures without the wires on part of his layout. He keeps changing the era of this layout, and I have not been there in a while. He is only about an hour from me.

https://www.youtube.com/watch?v=r3tbv2tRKS8

I will see if there are videos of any of the other layouts around here.

Sheldon

It would be a real treat to watch one.

Rich

One concern with ‘fabricating’ catenary out of wire is stiffness. If the wire is soft, it kinks and deforms easily (and looks and runs like hell); if the wire is hardened in a jig, it becomes impossible to straighten if kinked and is a health hazard (think cheese planers all over the layout!)

The etched brass cat/messenger/trolley and pulloffs were intended to be a structure with no inherent fabrication strains that could be formed with the appropriate side-to-side ‘wiggle’ to decrease pan wear, and that could easily be blackened or ‘verdigrised’ for better appearance. There was at least one company that made PRR (Gibbs & Hill)-specific ‘insulating’ components in O scale – it might be possible to adapt 3D printing to make suitable parts, even if you had to dip them briefly in solvent or otherwise smooth the ‘aliasing’ steps.

I periodically wonder whether some form of constant tension could be modeled to make deflections in the trolley wire somewhat self-restoring. As a matter of overkill (but effective operation) it’s inexpensive in cost to use commodity watch jewels in pantograph bearings in HO scale or larger to make a lightly-sprung pan articulate without binding – as with the real thing, you want a very long, soft spring for at least the final part of the lift and ‘tracking’ range.