As Rob has noted, the inexpensive Weller iron is fine and not crap. I bought one about 6 years ago and it’s worked just fine. Looks like experience varies.

I have to say, I have never heard of tinning the rails. I always understood that you just should tin the soldering iron tip before attempting any type of soldering task.

That said, I do tin the ends of feeder wires or wiring from signals.

Rich

Same.

Same. I never tin the rail first. A properly prepared joint doesn’t need this step.

Cleaning and tinning the tip is a completely different thing. Heat transfer from the tip needs to be as immediate and complete as possible; coverage of the liquid solder needs to be as smooth and, frequently, ‘capillary’ as possible; it’s important not to starve part of the joint of solder flow, or have part of it start to ‘freeze’ before expected (if you’re not using eutectic solder).

A plated tip is supposed to accomplish some of these things whether well-wetted with solder or not. Problem is that as the plating wears or is abrasively cleaned, it becomes harder to ‘wipe clean’ and more inclined to hold dirty or oxidized material. At some point, especially with certain tips from places that value price over plating integrity, the tips will wear to the point their base metal (usually copper or a copper alloy) is exposed.

Now copper is a good conductor of heat, but copper oxide less so, and hot copper loves to oxidize and corrode in a variety of ways, none particularly conducive to soldering ease. What you want is to clean and burnish the copper, and then seal the ‘pink’ metal with a thick film of solder metal before it has even a whisper of a chance to start oxidizing materially. Then keeping this film maintained with “regular tinning” gives you all the advantages of a plated tip without replacement cost. (But the moment any copper gets exposed, you may have to re-clean and then re-tin the bare patches…)

Did someone contend otherwise?

Rich

Huh. I’ve got an iron with a Weller 50W #37 screw in unit. Nice large head. I bought it maybe 40-50 years ago–sometime in the last century. It’s got the original plated tip, in fine form.

I’ve cleaned it with wet paper towels for about forever.

I DON’T let it get too hot too long. If it’s going that direction, I unplug it, and cool it down by wiping with, yes, wet paper towels.

Ed

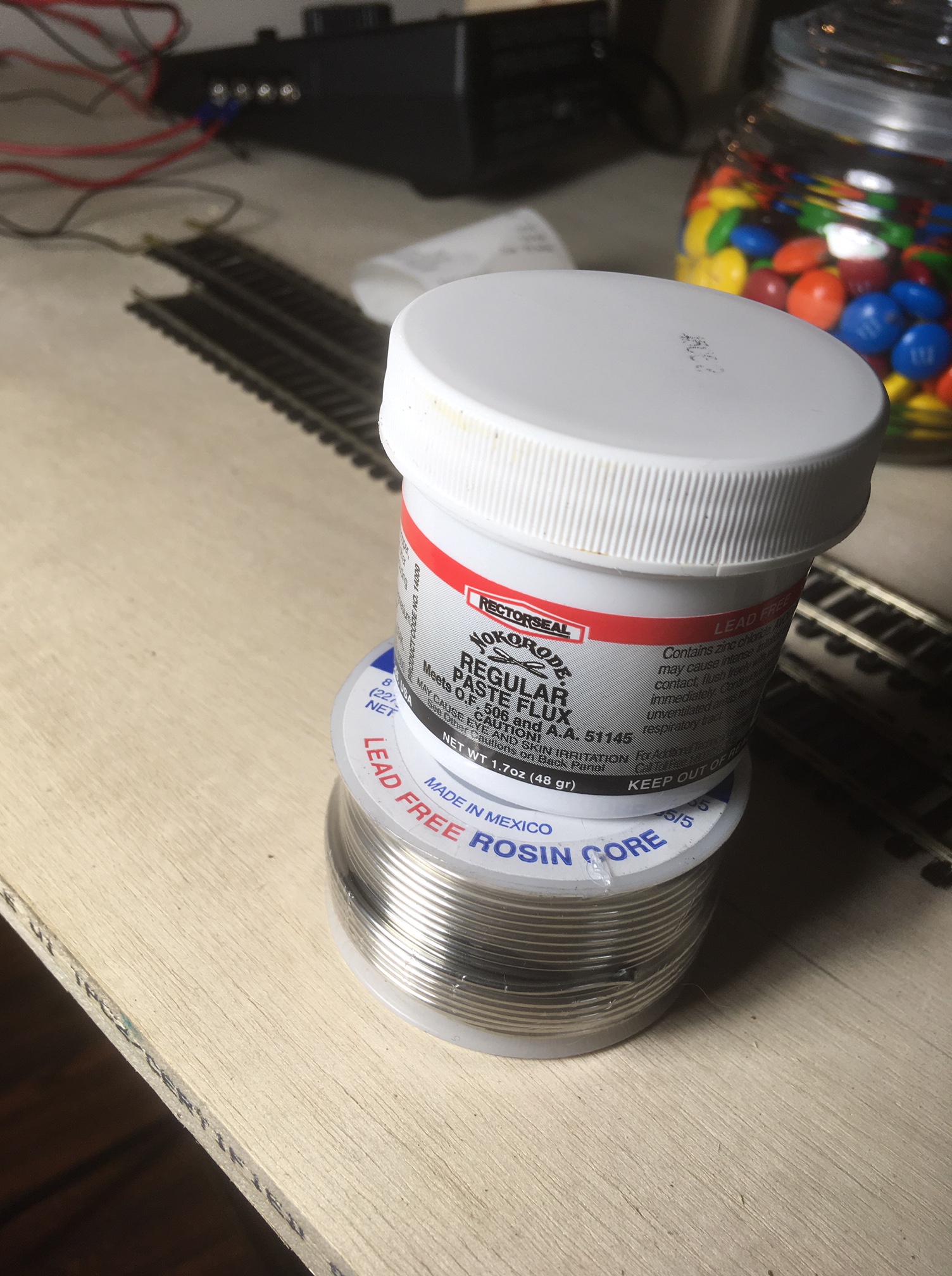

Guys, here’s what the local hardware store had. Someone here told to make sure the flux I bought was not acid but rosin. Maybe I misread, but in the store, the rosin/acid issue seemed to be around the solder, not the flux. I bought rosin-core solder, and I got the flux shown below. Did I get the right stuff? My thought is, the hardware store stocks soldering stuff for electricians and plumbers, not modelers.

Also I picked up an 80-watt Weller iron. Tip seems too big now that I look at it.

Rosin core solder is just that. An inner core of rosin with a solder jacket around it. Hard to tell from your photo, but the flux should be rosin flux, not acid flux. Yes, there is flux in the rosin core solder plus a separate flux applied beforehand to facilitate the spread of the rosin core solder.

Rich

.

It looks like you will be OK with that jar of flux. It is acid-free. Here is what the marketing pitch says about it.

Nokorode Regular Paste Flux is a lead-free, all purpose, soft soldering paste flux ideal for use with 95/5 and other common solders. Nokorode special oil base protects the solder joint against corrosive attack. It cleans and fluxes all at one time.

Features

- Cleans and fluxes in one operation saving time and money

- Flows smoothly into even the smallest cavity

- Multipurpose for use with 95/5, 60/40, 50/50, and 40/60 solder

- Lead free and acid free - safe to use on potable water systems

- Special oil base protects the solder joint against corrosive attack

Rich

You don’t need resistance soldering to solder. I use a Weller 23 w iron and it works just fine. Keep the tip clean, retin it every time you use it, scrape the rail where you are going to solder (it helps).

Get some junk track and practice. You will never be sorry.

Also, for the record, last layout, every piece of rail either had a feeder, or was soldered to a rail that had a feeder.

[Y][Y][Y]

Rich

Nokorode data sheet for #14000 says “NOT for electronic use”

APPLICATIONS: Nokorode® Regular Paste Flux can be used with 95/5, 60/40, 50/50 and 40/60 solders. It can be used on all solderable metals including copper, tin, zinc, nickel, and sheet lead. Do not use on stainless steel, aluminum or magnesium. Not recommended for electronic use.

I would say it is for plumbing and sheet metal.

https://rectorseal.com/nokorode-regular-paste-flux-group/

In my 65 years I’ve never used lead free solder, either. I don’t know how much luck you’re going to have with that. What diameter is your solder? Most of my layout soldering wotrk is with .032 and .020 solder. For decoder and PC work I use .015.

95/5? For plumbing.

https://www.oatey.com/products/oatey-955-lead-free-plumbing-wire-solder-216233657

Good Luck, Ed

Ed, I agree that rosin flux would be best, but since his flux is lead free and acid free, wouldn’t it be safe for soldering rail joints? You would not want to use it though on electronics boards.

Rich

What’s a flux brand you guys use? I could just look around until I find the exact stuff. And solder.

Acid flux is a NO NO NO.

Zinc chloride is not far behind.

Rosin-core is nifty but in many cases you need more ‘flux action’ than that tiny dried-up paste provides.

DO NOT USE PLUMBER’S ANYTHING. Plumbing requires aggressive flux to bite and clean large areas of pipe and fittings. The solder is the antithesis of what you want for most fabrication or electronics work – the alloy is purposely made to stay ‘sludgy’ as long as possible so wiped joints settle in to be water or pressure tight. No one cares if the pipes wind up stained or blotched and difficult to clean afterward.

What I advise is finding a good solder specialty provider (there are several) and getting a liquid no-clean flux – these come in greater and less activity; you won’t need high activity (which sometimes includes that zinc chloride corrosive). A small bottle of good no-clean will last a long time in this hobby. In the meantime here is a link to the SRA store Ed quoted in his post (he uses their #135 rosin paste flux).

You may still want to clean the joint after “no clean” flux has been used, but it won’t have the nasty issues that acid or the wrong kind of rosin blobs have. There are special flux cleaners. Most of them are chemically awful. I’m not going to be Nanny and say stay away, but know really, really well what’s in them and how to use them right before you open them up.

No, and I’m not being argumentative. I just want to establish that tip hygiene is different from ‘tinning’ wires and parts prior to assembly.

IF I’m not mistaken I put a link to the flux I find to be very good in my first reply on page 1. Maybe you didn’t like that stuff?

https://en.wikibooks.org/wiki/Practical_Electronics/Soldering

For years I used 60/40 for electronic work. I liked it fine. Then when eutectic 63/37 was deemed preferable I switched to that which took me a while to get used to. So for someone just getting started to try to solder feeders and joiners to rail with lead-free 95/5 would be a real challenge.

If the manufacturer states “not recommended for electrical work” that’s enough of a suggestion for me to steer clear.

Kester is one of the best brands out there, 63/37 is a good all-around alloy for wiring and electronics. .031 is a handy size but if you get into finer work, say on PC boards or decoders you might want to look at some .020 even .015.

Regards, Ed

There will come a day again after some 40+ years gone by. I’m writing all this solder stuff down Ed[Y]

TF