Saw a picture on the net of a movable frog turnout that creates a solid rail in the frog and switchs when the points switch. Anybody know of a location in the USA?

I’m sure there are lots in the USA, but mine was on my layout here in Canada.

I wouldn’t be surprised if Sheldon will have some on his new layout, too.

They’re also often seen on real railroads, especially for high speed trains.

Wayne

Amtrak northeast corridor, BNSF/UP powder river basin, UP around Chicago on Geneva Sub (Metra) are some examples

UP is biggest user

They’re common on the major railroads now. Most of the dispatcher controlled switches on the UP across Iowa have moveable point frogs. Some of the CNW installed switches with regular frogs still exist in some places. Almost all UP new or replacement dispatcher controlled switches are equipped with them.

Jeff

Hello All,

Can you post a link or photo?

Hope this helps.

Also called a “swing nose frog”. The tall thing with a sign on it is a blower to blow air over the frog in the winter so it doesn’t get jammed with snow and ice. The duct work is for the blower. The three part silver thing behind the ductwork on the ground is the switch motor to drive the frog point (just like a dual control motor on the switch points.)

To put this in a little context, see the difference in this picture (from an earlier thread) that shows this frog design in context.

https://www.railpictures.net/showimage.php?id=240339&key=8928380

Note that this does not involve a stub-type ‘perfect’ full railhead contact patch through the frog area, as some higher-speed designs use. But also note the difference between the heroic mechanism assuring correct geometry under load for the switchpoints proper vs. what is needed for the little movable point in the high-speed frog…

Since the frog point needs to be able to move back and forth doesn’t that expand the gap to the stationary rail in the direction it is thrown? Is that a potential problem from the constant impacts from the wheels?

Don’t understand which gaps you are talking about. The whole idea of a moveable point frog is it eliminates the gap and provides a near continous surface to eliminate impacts.

Doesn’t matter because there’s no way a wheel will touch the ‘expanded’ side gap. When the swing nose is aligned with a ‘stock rail’ there is nearly perfect metal support for the gauge corner across to the rim edge of the contact patch on the wheel, all the way from the tip to the curved joint hinge or flexpoint at the ‘heel’.

This also tells you why flange bearing in such a swingnose frog is not needed, as it is in a high-speed diamond crossing or some higher-number conventional frogs…

I assume the frog point has a pivot at the back end that contacts the rails after the frog and the switch machine pivots the front against either rail on the entry end. It should be impossible to move the front if the back ends are flush with the rails in both positions. So if the point is moved in one direction the back end in that position is rotated away from the exit end to some degree. This may be an extremely small gap or as much as 1/4". When the wheels get to the back end of the frog I am wondering about wear to the ends of the frog and rail.

There’s enough flex in the length of the rail that makes up the frog that no pivot is necessary.

Movable frog point by Steve Cox, on Flickr

Movable frog point by Steve Cox, on Flickr

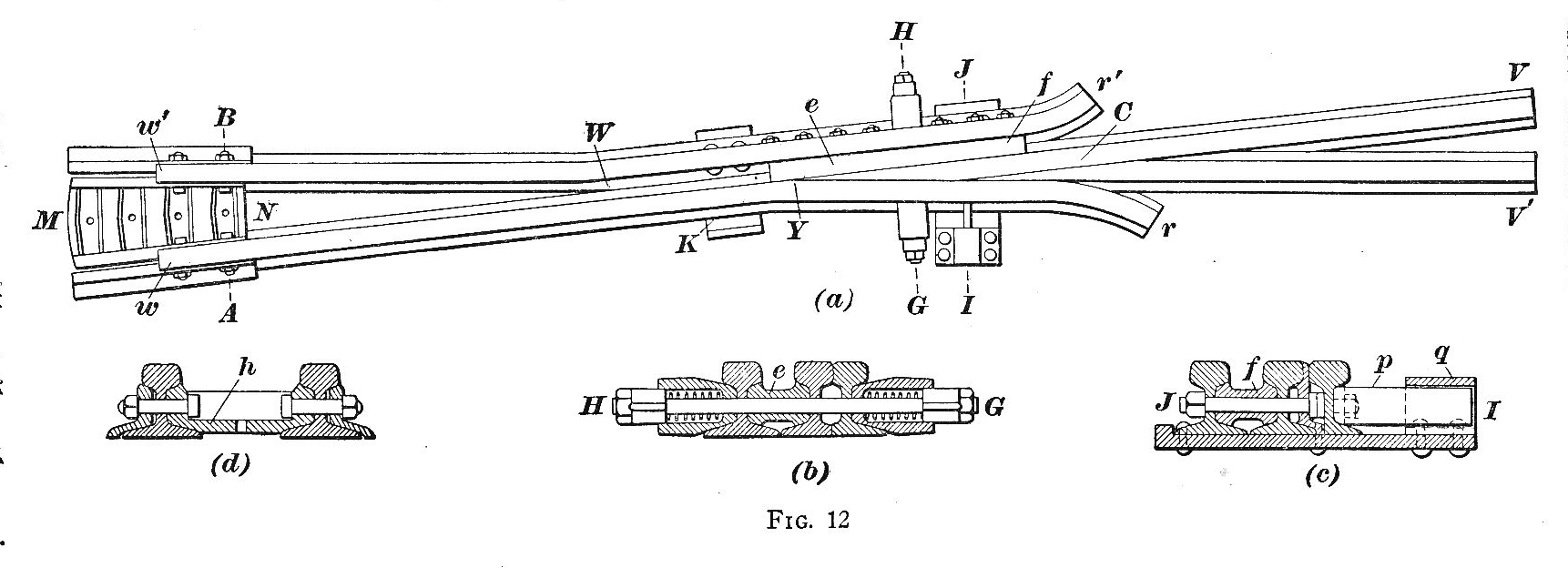

Note the rails that make up the “moving point” are very similar to a pair of switch point rails side-by-side in that they nest due to their being carefully machined so that the base and head practically form one piece of rail but there is a “sliding action” between the two.

Three switch motors are required to operate this movable point frog turnout:

Switch with movable frog point by Steve Cox, on Flickr

Switch with movable frog point by Steve Cox, on Flickr

Note, too, that each motor is driving two tie bars through linkage (four tie bars total on these long points.

Good Luck, Ed

Ed wrote: “Three switch motors are required to operate this movable point frog turnout”

On Amtrak, and perhaps on Metro-North as well, the 80mph crossovers have FIVE motors per switch. Three on the points, two more on the movable frog.

That means TEN switch motors for a single crossover. If something doesn’t work, the maintainer has to check all of 'em…!

And if for some reason you’re on the engine and have to get talked by a signal to go over these, you’ve got to be watching out for misalignment on the frogs as well as the points…

There is no pivot on the frog, just like there is no “pivot” on the points. The rail bends.

Note that in the picture I linked, there are EIGHT motors on the points and three on the frog.

There’s also spring-loaded frogs. Frogs move as well, but no motors, and they return to normal after you go through them.

They’re going to really only be in locations where there’s heavy traffic, like intermodal, or automobile transport. I think that you’re going to want to look along UP, or BNSF mains for them. Not sure if NS has any off hand.

- The àpproach to the Soo Line’s Ashland, WI ore dock had a sprung frog. Sadly torn down.