I just received my new Broadway Limited NP 4-8-4 engine and am looking for advice on ways to improve performance. I’ve run it on our Willamette Model Railroad layout with LARGE curves and turnouts and it still stalls and restarts frequently. Both the 8 drivers and tender wheels have elecrical pickup and appear clean. Also the lead and trailing 4 wheels frequently jump off the track at a turnout. Both the front and back sets have a spring to hold the wheels down but they are very light springs. Any suggestions on making this beautiful (very expensive $900) engine rum smooth will be appreciated. Capt. Brigg

How does one obtain and install the Broadway Limited “GO Pack” keep alive circuit in my new NP 4-8-4 Paragon 3 decoder?

This thread brings back bad memories from years ago when I bought the BLI Paragon 2-10-2 and 2-10-4. Lots of starts and stops, front and rear trucks derailing, and the driver wheels derailing on curves.

It took a lot of running to overcome the starts and stops, but eventually those problems went away. I had to send both locos back to BLI where they installed stronger springs, and the front and rear truck derailments went away. As far as the driver wheel derailments, the blame was on my 24" radius curves, so I wound up selling both locomotives.

Rich

Several of my recent BLI locomotives have behaved just the way you describe with your 4-8-4.

Two of the worst culprits were both PRR K4 Pacifics. One had an older version of the Paragon3 decoder and the Go Pack had to be soldered in. The streamlined K4 had a later version (H) decoder that had the Go Pack plug built into the board.

Does your box have a yellow sticker saying it is “GoPack Ready” or words to that effect? Then it is a simple job of lifting the tender shell and plugging the Go Pack in.

BLI_K4_cap by Edmund, on Flickr

BLI_K4_cap by Edmund, on Flickr

There are instructions for soldering the Go Pack here:

I was pulling my hair out trying to figure out why both of these big, heavy K4s were frequently stalling. The older one has the big coast-to-coast tender with sixteen wheels!

BLI_K4_cap2 by Edmund, on Flickr

BLI_K4_cap2 by Edmund, on Flickr

Sometimes they would stall in random places but there were two turnouts that they would always stall at. These were #8 turnouts with powered frogs and I checked every rail segment for power but to no avail.

The Go Pack solved the problem. I’ve read several other reviews of recent BLI steam models and the stalling has been mentioned by others as well.

I still have issues with programming the address on the P3 decoders but that’s for another thread.

Good Luck, Ed

I think it’s a combination of at least two problems with BLI steamers:

a. Their tenders are too light; and

b. Their drivers don’t make good contact with the rails consistently, leading to continuity problems (hence BLI’s introduction of the keep-alive bomb).*

Historically, I have had problems with my Paragon and Paragon 2 steamers where diesels and electrics don’t seem to have those problems. They can go for weeks running rather well and pleasingly, but then they start to stall, restart the decoder, and stall. I haven’t dealt with this problem constructively yet because I have other locomotives I can reach for, unpack, and put on the rails to complete a play session. I suspect that the tires need a good cleaning, maybe the springs in the bearing boxes need cleaning, or something along those lines. I can’t help but wonder if Conducta-Lube might be a good solution at times on the wipers, but I don’t have any and have never tried it.

It might be worth noting, too, that when BLI was selling their BlueLine, PCM, and Paragon models, none of them had de-facto traction tires. They came along as a factory default starting in Paragon 2 somewhere, and they have been a staple ever since. It was with my first Paragon 2 locos that I began to get the stalling problems. Some worse than others. My P2 Hudson and Niagara are notable examples, but my Santa Fe 2-10-2 and the I1Sa Pennsy 2-10-0 run very reliably.

All of my articulated engines, from a Lionel HO Challenger, to a Rivarossi H-8 Allegheny, to a PCM Y6-b 2-8-8-2, and the various BLI Hybrids run like Swiss watches. Same with my Trix 2-8-2 and a GG1…they run like tops.

*I said it’s a combination of things, and in the case of poor pickup tire contact, the rails are often just as much at fault as the tires. I don’t mean they’re not clean…most of us clean the bejaysus out of our rails, often several times in order to get our intracta

After reading one of Ed’s response to Broadway Limited engines in another MR post I decided to open the tender on my new NP 4-8-4 Paragon 3, revision “H” and check it out. It is ready for the plug in “Go Pack” and I have ordered one through my favorite hobby shop, Portland’s Hobby Smith. There is also lots of room in the tender for the capacitor pack. There are several good videos in Youtube about installing the Go Pack.

I also found that the rear light on the tender is not lighting and there is a wired LED that should be working. I made a deal with the hobby shop that I would fix the rear light myself if they would discount the Go Pack. That saves them (and me) from sending the engine back to BLI. They were happy to comply. Thanks for the information. Capt. Brigg; CEO Pacific Cascade Raillway in HO gauge.

Sounds to me like BLI is trying to overcome poor design/manufacturing/pickup issues with the Go Pack “band-aid”. You shouldn’t need a “keep alive” for a locomotive that large. I bet my late 70s brass steam locomotives have better pickup than that BLI 4-8-4. [:S]

Tom

I agree with you, Tom. It is inexcusable that a locomotive that large and expensive should need add-ons to make it run properly.

None of my older BLI Mikados have contact issues. Makes you wonder about their newer stuff.

A lot of BLI has issues, my only one is in pile to be e-bayed. I hear MTH has issues on some stuff too but personally have not experianced that.

Just to clarify, just the paragon 3 motors/boards. Their paragon 2 stuff was fine.

I agree. I remember getting my first P3. It was the PRR H10 and it stuttered and died from the first moments I placed it on the track. BLI sent a new decoder which I replaced. No improvement.

Then I sent the engine to them for another decoder and harness replacement. Got it back with still no improvement. Put in an ESU decoder and it has been running fine ever since.

Also 3 BLI heavy pacifics, plus the two K4s, a light Mikado, all 3 of my P5a electrics (all 3 motors bad, too) all had decoder issues and even after “factory service” they’re still behaving badly.

I’ve budgeted replacement decoders from other vendors for all these engines in the future.

Something went bad with the addition of the “Rolling Thunder” transmitter to the board. They need to reevaluate their electronics from the ground up.

Regards, Ed

I have posted the story before about what I went through with my BLI 2-6-6-4, so I am not going to type it all in again.

They have problems, and they need to do more to help their customers when we get stuck with those problems.

Spending that kind of money on a model, we are well within reason to expect flawless performance.

-Kevin

All seven of my BLI/PCM steam locos run great…

After I rebuilt two from the ground up and removed the decoders from the five that came with decoders and rewired them for DC. (Two were “stealth” models from the PCM days)

And those five all have Bachmann tenders now…

Ironic that a company that impresses me as selling the sound experience as much or more than the model experience has so much trouble with electronics.

None of my $200 Bachmann locos have these problems, but then again they don’t have decoders either…

I see no more BLI locos in my future, unless they are dirt cheap for me to invest in rewiring them.

Did I read someone mention tender weight? Yes the tender is likely too light for good tracking and electrical pick up. And yes, a long rigid wheel base like this will be fussy about track, even with sprung drivers.

Sheldon

I would have done the same thing if I would have never sent the 2-6-6-4 back to BLI that last time. Now I have an empty spot on my roster, oh well.

My only other articulated locomotive is my Bachmann 2-8-8-4, and it is many times over a better locomotive than the BLI 2-6-6-4 was.

-Kevin

Ive resorted to only buying paragon 2 stuff. I love the paragon 2 sound, whereas I dislike the p3 sound. P3 also has those bugs, yet more expensive. When you’re someone like me who prefers buying discounted used, there is very little reason to choose p3 over p2. The only p3 engine I got is the L1s which I have yet to have any major issues with.

I’ll also be getting two of their Santa Fe 4000 class 2-8-2s…wish me luck.

Im genuinely curious how many modelers are using the rolling thunder system…considering how hard bli is trying to market it.

Charles

My $60 sound Bachmanns had less trouble than BLI, sure the sound is better on the BLI but we are comparing a sound value vs a top of the line.

I only have one BLI Paragon 3 locomotive: An SW7 switcher, which I’ll most likely sell because I don’t care for the gearing. I know that Ed purchased the Rolling Thunder speakers. I have zero interest in it. It’s more of gimmick and it wouldn’t add any additional enjoyment for me.

Tom

Indeed, its like BLI’s version of DCS, where the feature will only work with their own engines…so its only worthwhile if you stick with BLI and only BLI. Not to mention Im happy with how my engines currently sound.

I have had similar problems. I opened the tender and traced the tender pickup wires back to the decoder. On mine, I found the male end of the tender pickup wires to not be properly seated in the plug itself. I pushed the wires into the male end of the plug and most of my engine problems went away.

Now, if the engine does stall, I lightly touch the coal load on the tender and away it goes. So the next time I open the tender, I will add a little weight (maybe 15 grams or so) and determine if that resolves the problem. If that is unsuccessful, I will install the BLI “keep alive”.

It is a beautiful engine and I waited forever for it to become available. When it is running well, it is impressive and pulls my NCL varnish nicely.

Yesterday, 2/24/21, I installed the BLI GoPack keep alive and the engine now runs fine. Hurray!!!

— and a week later packed the whole thing up and sent it to Cuda Ken. He has been enjoying it on his layout.

I can’t say, in my experience anyway, that tender weight is the culprit here. The poor electrical continuity seems to have reared its ugly head with the transition to Paragon 3. Again, most users seem to not have the problem with earlier P2 and QSI locos and the tender weight hasn’t appreciably changed with the P3 introduction.

Just last night I dusted off an old QSI-equipped Hudson I had purchased in 2002. It hadn’t run in years and when I ran it last night it was performing without any signs of trouble.

Something seems to have compromised the design with the addition of that P3 “rolling Thunder” transmitter that is piggy-backed on the board.

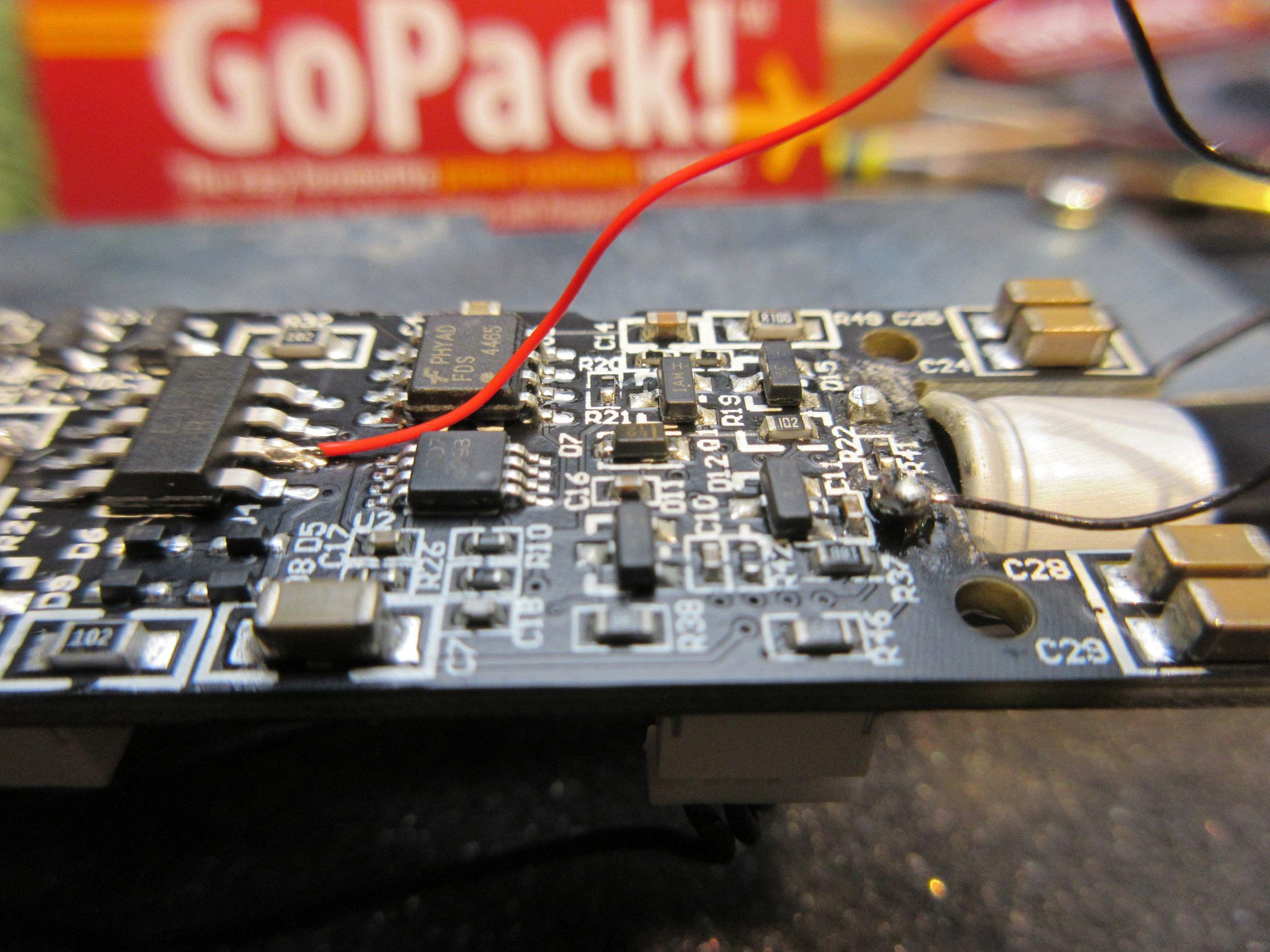

IMG_5183_fix by Edmund, on Flickr

IMG_5183_fix by Edmund, on Flickr

The transmitter is the smaller board on top with the blue antenna wire.

Regards, Ed