So as part of the response of Northeast Wisconsin to get CN to keep operating it’s lines up into the North Woods. They figured out that CN can start carrying logs from the North Woods to the mills of the Paper Valley between Appleton, WI and Green Bay, WI. CN said it would like to have the cars but so far the business has not proved resilent enough for CN to buy the cars. So apparently the State or the Communities of NE Wisconsin are going to pool their money and buy 150 new log cars for CN. Just read about that currently. Another item they are discussing was opening a TOFC ramp or collection point in Green Bay or Menominee. They say the closest one otherwise is in Chicago and they feel they could generate some container traffic if CN would open a yard further North. We’ll see what happens with this next initiative.

Can I presume log cars are so specialized that no one leases them, or is there some other reason why they can’t just lease them? Might CN have their own idle log cars with the shut down of much of the former BCR Dease Lake line?

From what I understand CN’s position is yes they do have their own log cars via WC and long ago purchases but there is currently a shortage of them as CN is also cutting them up for scrap. The lumber suppliers stated to WisDOT in a survey they could load and ship more freight if they were supplied with more log cars.

CN is hesitant to buy them itself because it does not see a long-term need or feels this is just a short-term shortage, not sure which. I looked at some youtube videos Youtube SEARCH CN Hayward, WI, looks like they have plenty of log cars to me but that is just looking at passing frieghts and they do look pretty old and messed up though…so maybe they are near retirement? Also, unsure of the last question.

Kind of weird if you ask me because you think CN with it’s deep pockets would just buy them itself. Then again if the log cars are only going to be used to ship from Michigan UP to central Wisconsin…it’s not a long haul.

Freight cars have long lives, now 50 years permitted, and are not cheap. It would seem that the shippers themselves are reluctant to make a long term commitment by buying or leasing their own cars, so it is not too surprising that the railway will in turn be averse to buying a fleet of specialized cars for what may be a short lived use. I presume the existing log cars are coming to the end of their mandated 40 or 50 year life.

It doesn’t matter how deep CN’s pockets are. No rational entity will make an investment unless there is a decent opportunity to earn back the money with a good rate of return. Apparently, CN doesn’t figure there is such an opportunity.

Northern Wisconsin has an economic problem. Paper making was a significant industry there. But the paper mills have been closing due to a decline in demand for paper. There’s really nothing anyone can do about this. Acquiring 150 cars to haul logs to still operating paper mills is but a futile gesture.

OK this is not the article I read but I found this from 2015. I believe the TIGER grant process failed because they are issuing bonds now and the number of rail cars is up to 150 vs 115…though it could still be 115. I am sure they are issuing bonds now for them vs TIGER grant. The article I read said just Wisconsin but below says Michigan as well, not sure if that point has changed.

http://www.centralcorridors.com/wcg/pdfs/GLFR_TIGERVII_2015_Project_Narrative.pdf

If CN does not expect sufficient return on investment to purchase the cars, why does Wisconsin expect it to be worth the investment? Or is this just a public subsidy to the paper industry? Even a subsidy should have clearly defined economic rationale. What it is?

Keeping what paper industry that currently exists in Wisconsin continuing to operate in Wisconsin, continuing employment of Wisconsin residents and continuing tax revenues from the paper industry. If the paper industry leaves, former employees instead of paying taxes (state income) go on the unemployment rolls (state out go) and there are no taxes collected from the industry.

Not being a CN rail guy my presumption is most Class I railroads would rather haul privately owned cars vs railroad cars #1. I think the #2 reason is risk, if the railroad cannot find anyone else that wants to put skin the game, why would it do so. #3 I think the rail haul in most cases is so short it probably takes the rail car 15-20 years to repay it’s original cost.

I don’t think there is a mass movement to shut down paper mills in Wisconsin or that the industry is in much decline. I could accept gradual decline. Paper Mills are a huge consumer of Engineering students from both UW-Madison as well was UW-Milwaukee, they seem to have very deep pockets still. One of the largest firms is Kimberly-Clark which has extensive operations in Wisconsin just to support the Manufacture of Huggies disposable diapers…pretty sure and as a stockholder, that Company and that product is going to be consumming pulp wood for a long time to come in Wisconsin. Anyways, this isn’t the Northeast and the same Economic pardigms do not apply, in my opinion.

Why the paper mills do not fund the railcars is another question but I think the answer is they are not in and do not view themselves in the transportation business, if nobody buys the railcars they will just shift over to trucks more. More logs on trucks is something Wisconsin does not want because of the damage to roads and how hard it is becomming to find log truck drivers when they are being sucked up by the Baaken Oil fields of North Dakota…which pays more.

If sourcing logs becomes a problem in W

During Soo Line days in the Mich. UP, they used gondolas with end hight extensions to carry 8’ pulpwood. They could be loaded with the pulp truck claws, and I guess they would probably have to have been unloaded also with a claw. I see the new design would be more efficient unloading with a fork lift. The study quotd also answered my initial question, that there are no log cars for lease. The study also answered another poster’s question, that the economic benefit to the public in the area would more than compensate for the cost of the cars.

Seems this this would be a good opportunity to make a “intermodal” log carrier that could be used on a flat or even a well car.

That sounds like a good idea. Fabricate a log rack that could ride on existing rolling stock. There is probably plenty of idle manufacturing capacity in Wisconsin to build them locally. Would there be any obstacle to that approach?

Could somebody post a photo of one of these 150 new log cars?

How specialized are these cars? Couldn’t bulkhead or regular flatcars be used for this? Or is the problem just that there are not enough cars of any type available?

(edit): I just re-read earlier comments on this thread and realized that Mike had posed essentially the same question. Don’t railroads or other owners regularly modify or re-configure cars? If these new cars don’t work out it shouldn’t be a total loss.

If you looked at the WI document you would see that these are purpose built cars. That is typically the case for new cars where the objective is to minimize tare and maximize tare within gross weight limit.

To reconfigure cars, you have to have something reasonable to start with.

Mac

The new cars have not been ordered yet they are getting approval for the bond issuance to fund them. Here is a video of a CN train with the log cars in it, towards the end of the video it shows them being loaded with a rather large backlog of lumber waiting…the second half of the video seems to imply car shortage.

https://www.youtube.com/watch?v=0yN2E4ABp0M

Another train carrying loads South and showing some of the light density traffic on the Northern Lines going into the UP which they are trying to fix with help from Wisconsin & Michigan…

Pulpwood trucks got to get into the woods, banging between trees, right up to where the iron mules drag up the logs. Pulpwood trucks are often owner-operated and maintain their own rigs. IM Log carriers would get really banged up, and trying to coordinate the IM racks supply with the independent pulpers would be a challange. The truck to train reload presently is done with typical logging equipment. Specialized IM loaders and pad would be a prohibitive investment for these backwoods log yards. Some of the transloads are simply a siding or two and the loading might be done directly from self-unloading pulptruck to railcar.

I had been wondering what “log cars” are–and now, I have the impression that they are what I knew as “pulpwood racks”–cars with bulkhead ends and floors that slope from the sides to the middle. I have watched them being loaded by hand from the trucks that brought the logs out of the woods.

A typical self unloading pulpwood truck in the process of unloading…

A typical pulpwood truck coming out of the woods - note logging “road”…

Soo Line bulkhead pulpwood gondola…

Typical pulpwood load-out siding…

Soo Line pulpwood train in Upper Michigan…

Wisconsin Central pulpwood car - note ability to unload with a wheel loader with grapple claw…

Wheel loader with claw attachment unloading from the side - this is unloading a truck…

The car you describe sounds like ones I have seen reference to down south. It seems the bottom was sloped toward the center so they could load 4’ pulpwood on both sides, sloping together in the center. In the Mich-Wis area they cut 8’ pulpwood, which filled the width of the car such as the Soo bulkhead gondolas pictured above. The new cars pictured in the gov’t study are bulkhead flats with side racks so the 8’ pulpwood can be loaded between the rack uprights, for easer unloading with big claws or fork lifts that fit between the uprights.

Here is a pulpwood load out siding on Kansas City Southern…

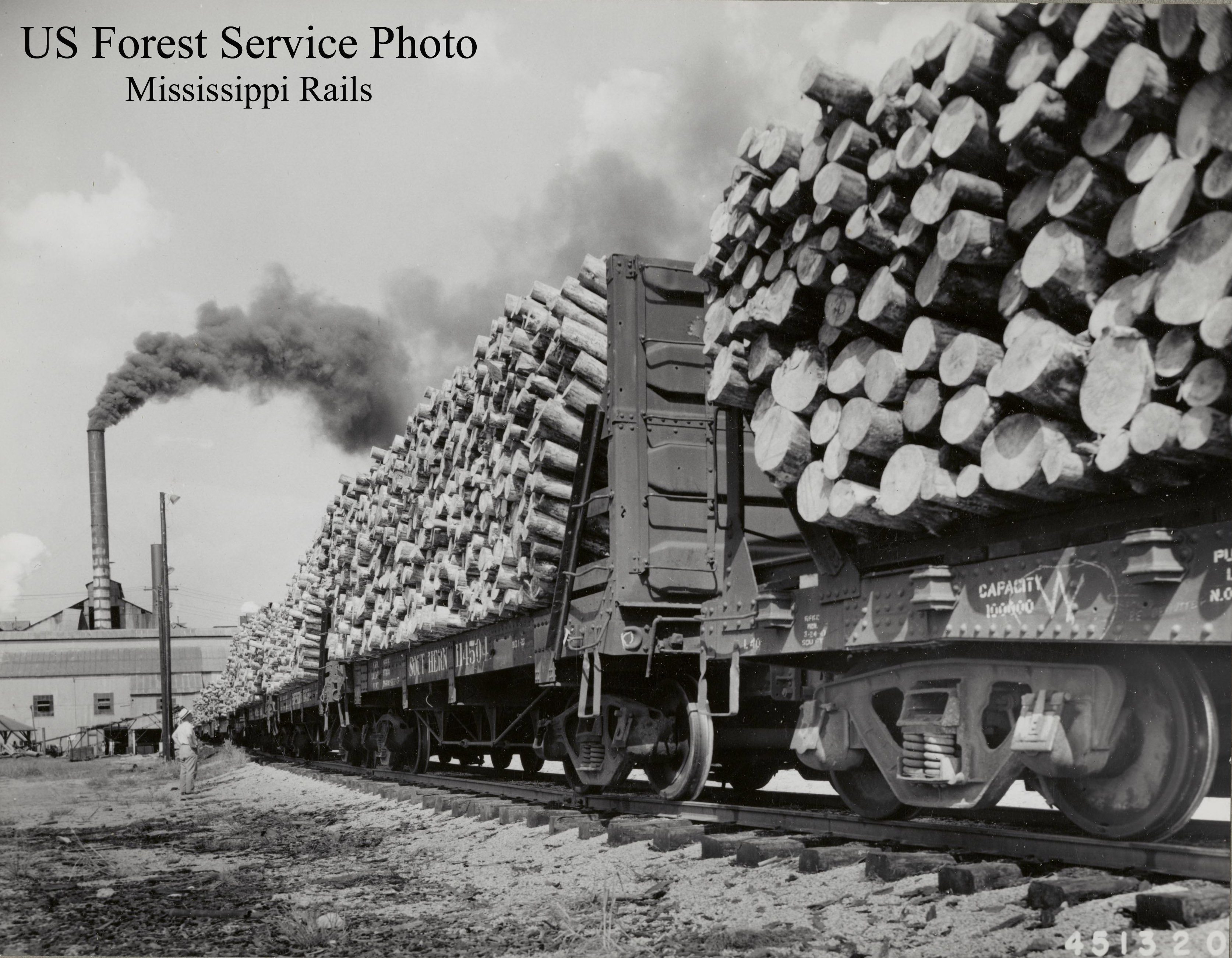

I believe these might be some of the cars that Mr. Deggesty is referring to - these are in Mississippi and it appears that the pulp is slanting inward in the manner previously described…

Here is a Southern car being hand loaded with pulp and one can see the inward slant of the pulp wood…