I have interest in adding a RIP track operation mechanic with randomized cards to my layout. I’m modeling the mainline of the PRR between pittsburgh and altoona. I cant find much history on detectors. What I’ve found is they started being used in the 40s but I cant find anything on how much use they had during this time specifically for PRR in 1953 as suggested by the title. Any info anyone may have is greatly appreciated.

Join PRR@PRR.GROUPS.IO. the group has experts on every facet of the PRR. I would bet if any did exist they will tell you the number and physical locations. Several members are former PRR high level employees who freely share their knowledge.

The defect detectors of that era would have only detected hot boxes and dragging equipment if they existed. Neither of which would have gone to a RIP track. They would have been set out and repaired in place on line. The vast majority of RIP track business is found with the two inspections every car has in the yard and then rejects from industry.

On the inbound side the exterior of the car is inspected for loose grap irons, defective doors, defective handbrakes, defective bearings, etc.

On the outbound side the brake system is inspected.

At industry, cars that are unfit for loading are rejected and returned to the railroad for reassignment or repair.

That’s really helpful thank you so much. I’ll take my idea for the detectors and apply it to the yard instead. Your explanation of earlier detectors gives me some ideas as well for adding some interesting wrenches into ops to spice things up instead of the same old same all the time.

If you really want to make an interesting scene, cut out a little pit and put this fellow inside his inspection hooch.

Car Inspector Pit_Juniata Scales 1-17-30 by Edmund, on Flickr

Car Inspector Pit_Juniata Scales 1-17-30 by Edmund, on Flickr

This was at the East End of the Altoona yard. Hump tower in the background. Note the two nozzles that would squirt a splash of white wash on to the offending car to be set out since, It would appear, the inspector couldn’t very well read the car number, although it was usually stenciled on the truck bolster. Still too hard for him to see. These cars would most likely be sent to the RIP track.

There’s an ebay seller that offers LED flood lights very similar to the larger ones shown here. They would have to be reduced in height but I have done this and easily made new brackets for them.

Good Luck, Ed

That guy does not look happy at all.

-Kevin

Actually he’s quite thrilled. He worked up to this job after doing twelve years on the spike-straightening pile:

BnM_Billerica-shop by Edmund, on Flickr

BnM_Billerica-shop by Edmund, on Flickr

Although he admits it can be the pits on some days.

Cheers, Ed

That is not the spike-straightening stage. See the multiple barrels? They are separating the left-handed spikes from the right-handed spikes for the other side of the rail as the new McGinnis management instructed, so they can be sold and leased back for future construction.

I don’t think IR hotbox detectors were deployed until later in the '50s. Most of the approaches before then were ‘self-contained’ like the smoke and stink capsules.

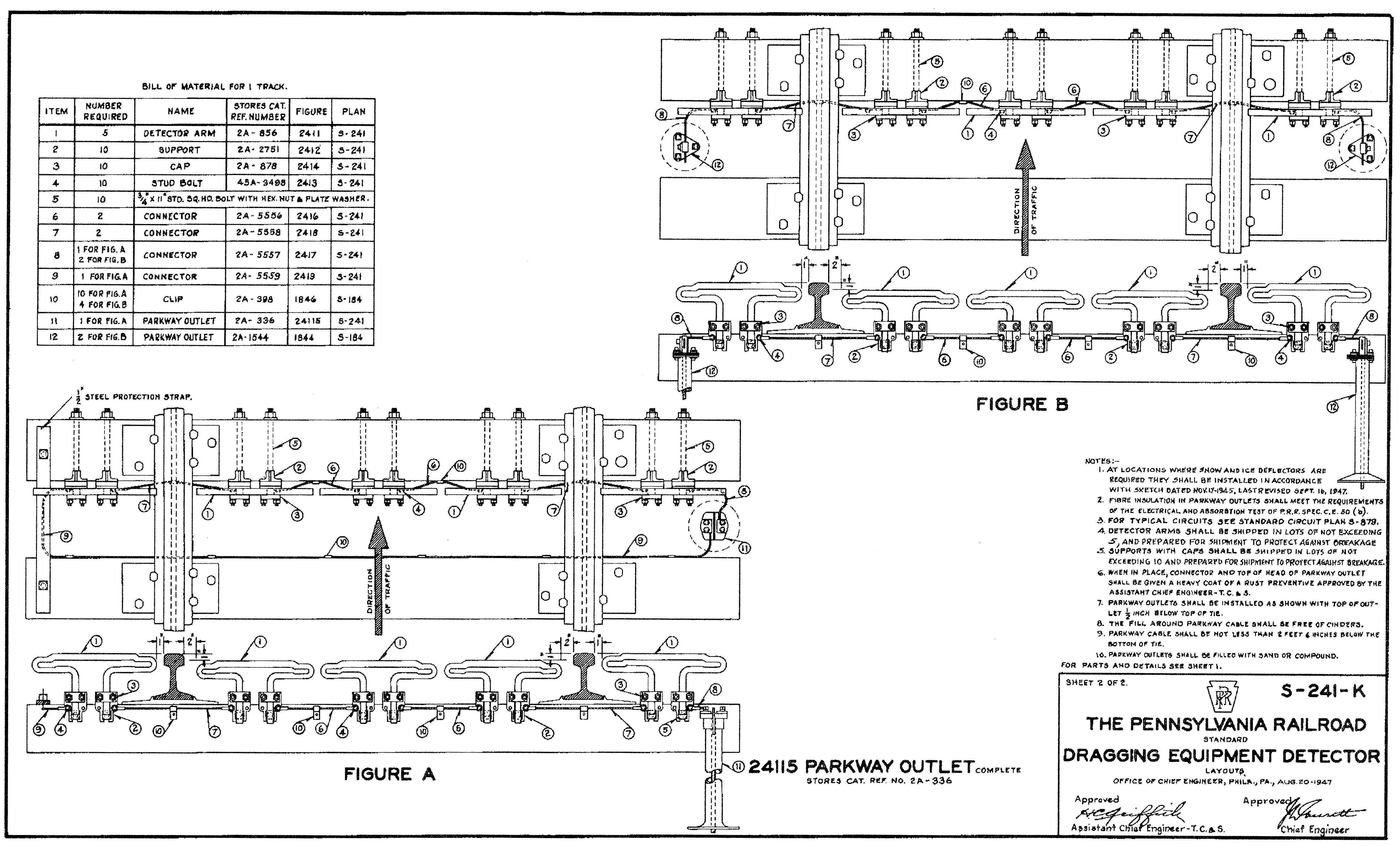

One ‘defect detector’ PRR used earlier was the flap-type dragging equipment detector. These can be fun to model.

I think in 1953 the “defect detectors” were primarily the railroad’s employees. If a train stopped a sidetrack for a meet, their crew would watch the train passing them and then signal to the caboose crew that everything was OK, or use hand signals to indicate a problem (like holding their nose to indicate a hotbox). Same thing would happen at stations, signal towers, crossing shantys, etc. Railroaders looking out for each other.

Not only that, but it was in Rules of the Operating Department

Somewhere in my stacks I have some photos of this type of early “non-automatic” reset dragging equipment detector.

Detector_PRR by Edmund, on Flickr

Detector_PRR by Edmund, on Flickr

You can bet they were a design of Union Switch & Signal, a favored PRR supplier. The gray iron “arms” were somewhat easily broken, nicknamed brittle bars, thus opening the series circuit and dropping the signal.

Good Luck, Ed

Ed, have you got a picture of the type used on the PC by the early’70s? These used a flap of doubled-over elastomer, a bit like tire-tread rubber, and a hinge below tie level with a crank and pushrod arrangement (I never found out precisely what tripping the presumably connected switch actually did…)

Overmod wrote: “I never found out precisely what tripping the presumably connected switch actually did…”

Amtrak had those “flapper-type” dragging equipment detectors on the Hell Gate line (they’re probably still there). When activated, it sent an alarm to the dispatcher’s office.

I was going west up the Hell Gate Bridge and got a call from the dispatcher that we tripped a DED.

Stopped on the curve just before the portals, walked to the back (8 cars), found the brake pipe hose had come loose and was hanging down. Got it secured, walked back to the engine, and we finished the run.

I am going to work that into the lyrics of the next coutry song I write.

Loving you was like spending

12 years on the Pennsylvania spike pile

Straightening, sorting, and bending

Life getting worse in the meanwhile

-Kevin

I hope it goes as high in the charts as this little ditty did!

Funny thing is, While doing some wheelbarrow work the other day I was actually playing this tune in my head… all the live-long day [8] [8] [8] [:D]

For a country song you have to work your dog dying into the lyrics somehow [:-^]

Happy Days ! Ed

Would it be like this?

Drag detector by Patrick, on Flickr

Drag detector by Patrick, on Flickr

I have some other books that may have a photo or two. I looked through my 1963 N.Y.C. Signal Dept. Diagrams and didn’t find anything.

PRR had a detector protector made up of dozens of cut-off lengths of air brake hose standing like soldiers spiked to a tie ahead of the detector. They called it a snow guard.

Snow-Guard_PRR by Edmund, on Flickr

Snow-Guard_PRR by Edmund, on Flickr

Had to find something for those apprentices to do. Note the 1940 date.

Regards, Ed

Yes. I think the linkage was different on the ones I saw but I can’t tell you how. The one I remember definitely had rubber flap loops – I looked closely enough to see the once-white fabric reinforcement in the edges – and a crank arrangement at the end; I presumed that when it deflected through a sufficient mechanical angle it would trip a switch alerting appropriate people that ‘something’ had moved it enough to count. It had spring return to upright (please don’t ask how I know that!)

In my opinion much better than a brittle-bar detector in many respects.

[quote

I believe that is an acoustic detector that trips when it “hears” something hit the metal guard.

If you have a timetable for the area of interest in the time period of interest, the special instructions should list defect detectors. If nothing listed then there might not be any.

I have a couple of questions about stuff I find I don’t know.

What is a ‘parkway outlet’ and why are the specific design details for them in S-241-K taken?

Why can the center rows of airbrake-hose segments be eliminated if the detectors detailed in S-241-K are installed, per the note for the snow guard?